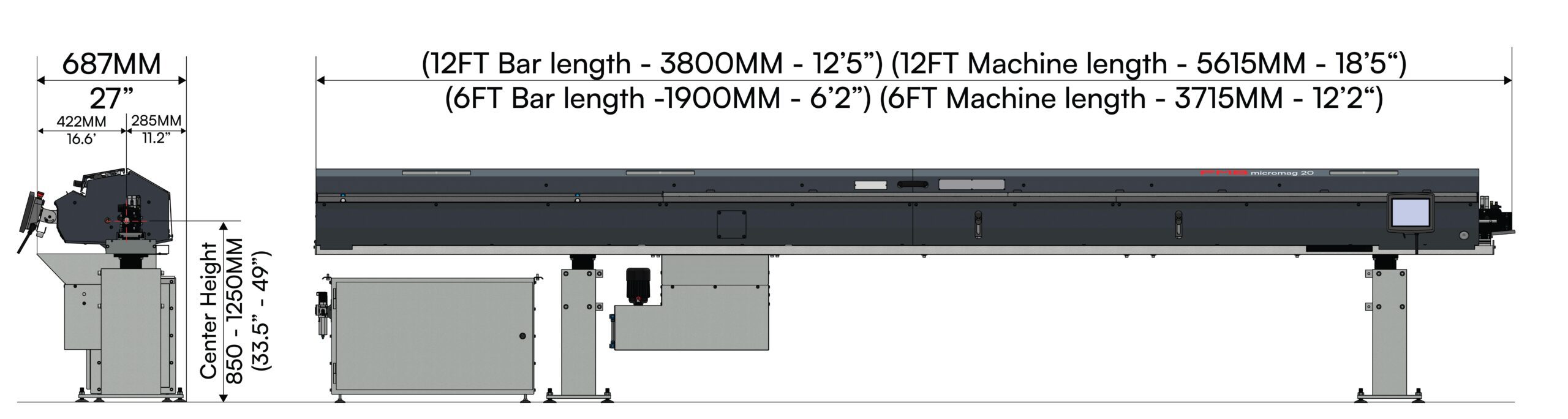

Micromag 20

Make: FMB | Bar Length: 6', 12' | Bar Diameter: 0.031” – 0.787”

The FMB Micromag is a magazine style automatic bar feeder for bar stock diameters ranging from 0.8–20 mm. This precision bar feeder is specifically designed for small Swiss type lathes used for medical applications.

Questions?

Call Sales (314) 692-8388

Features: Micromag 20 Bar Feeder

- Bar diameter capacity: 0.8mm to 22mm (0.031” to 0.866”)

- Automatic loading magazine – 9 linear inches of rack capacity

- Walking beam separation system – drops out of the way when running larger diameter bars (21-bar capacity)

- Polyurethane guide channel system – noise & vibration dampening

- Ultra-quick guide channel and pusher changeovers – 10-min full set changeover, 3 min within same channel set

- Hydrodynamic support via high-volume oil flow into channels

- Separate floor-mounted electric cabinet isolates electronics from vibration

- (1) Guide channel set to be chosen by customer. Several sizes to choose from, each handling a specific stock range. See table above (spindle liner required if channel set is not lathe’s max capacity)

- (1) Universal telescoping front nose and (1) nylon nose I.D. liner specific to pusher

- (1) O.D. bar stock collet to be chosen by customer (specific collet needed for each stock diameter)

- Swiss headstock synchronization device

- Automatic remnant retraction, self-centering gripper

- Custom lathe cable and interface plugs

- Polyurethane bushing blocks (2 pieces)

- Spindle tube nose assembly – available in 5mm, 7mm, 10mm

| Technical Specifications | |

|---|---|

| Bar Diameter | 0.8mm – 22mm (0.031” – 0.866”) |

| Bar Length | 1000mm – 3800mm (39.4” – 12’5”) |

| Magazine Rack Capacity | 228.6mm (9”) or 21 bars 4mm or less |

| Maximum Remnant Length | 320mm (12.59”) |

| Bar Loading Cycle Time | Approx. 25 sec for 12’ bars |

| Feed Force (Pusher Torque) | Max 300 N, adjustable |

| Forward Feed Rate | 300mm/sec (710in/min) max, adjustable |

| Return Feed Rate | 601mm/sec (1420in/min) max, adjustable |

| Power Consumption | 1.5 kW/2 kVA |

| Operating Voltage | 230-400 V/60 Hz – 3 phase |

| Control Voltage | 24V DC |

| Oil Capacity | 50 liters (13.2 gallons) |

| Oil Viscosity | ISO 64 cST – Machine oil ISO BG32 – Air oil |

| Compressed Air Supply | 6 bar (90 psi) |

| Compressed Air Consumption | ~3 liters per loading cycle |

| Machine Weight (w/out Oil) | 885 kg (1950 lbs) |

| Material Straightness Specification | 0.007” TIR/foot of material (V blocks, 6’ equidistant) |

| Guide Channel Sets | Pusher Diameter | Minimum Bar Size | Maximum Bar Size |

Max. Bar Size With Front Remnant Expulsion * |

|---|---|---|---|---|

| Ø 5 mm | 5 mm | 0.8 mm (0.031”) | 4 mm (0.157”) | 5 mm (0.196”) |

| Ø 7 mm | 7 mm | 1.6 mm (0.063”) | 6.4 mm (0.250”) | 7 mm (0.275”) |

| Ø 10 mm | 10 mm | 2.4 mm (0.094”) | 8 mm (0.315”) | 10 mm (0.393”) |

| Ø 12mm | 12mm | 2.4mm (0.094″) | 10.4mm (0.409″) | 12mm (0.472″) |

| Ø 13 mm | 13 mm | 2.4 mm (0.094”) | 11.25 mm (0.443”) | 13 mm (0.511”) |

| Ø 15 mm | 15 mm | 3.2 mm (0.125”) | 13.5 mm (0.531”) | 15 mm (0.590”) |

| Ø 18 mm | 18 mm | 6.5 mm (0.255”) | 16.75 mm (0.659”) | 18 mm (0.708”) |

| Ø 20 mm | 20 mm | 8 mm (0.315”) | 18 mm (0.708”) | 20 mm (0.787”) |

| Ø 22 mm | 22 mm | 8 mm (0.315”) | 20 mm (0.787”) | 22 mm (0.866”) |