Turbo RS 2-20 Bar Feeder

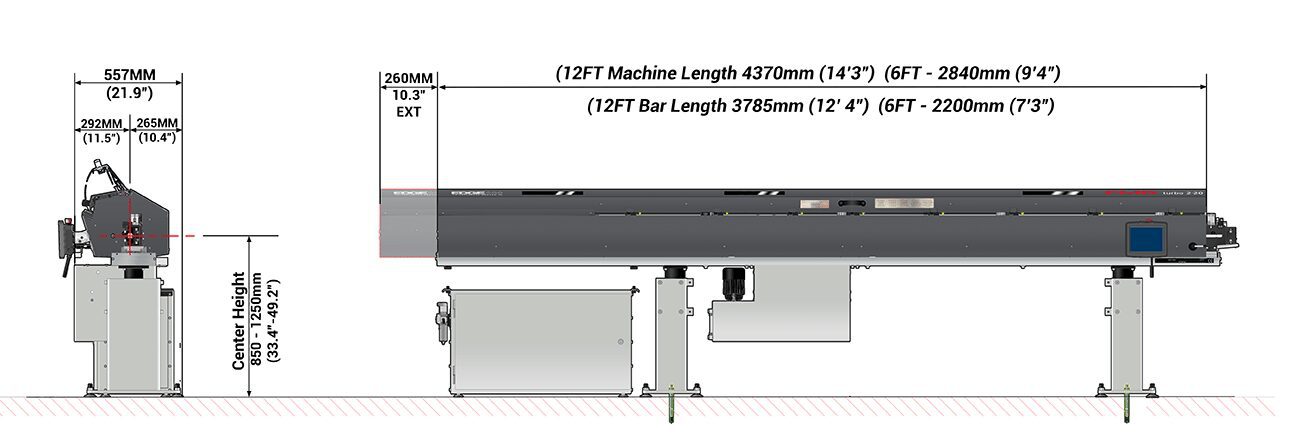

The FMB Turbo 2-20, available in either 6′ or 12′ configuration, is an automatic bar feeder for processing bars in the diameter range of 2-20 mm in lengths from 6’ to 14’ on CNC lathes.

Equipped with a Swiss type headstock synchronization device, peck drilling and threading on small diameter bars is simple and done with high-tolerances.

The Turbo 2-20 is designed to automatically feed round, square or hexagonal bars into CNC lathes.

Features: Turbo 2-20

- Bar diameter capacity: 2mm to 23mm (0.078” to 0.905”)

- Automatic loading magazine – 7 linear inches of rack capacity

- Polyurethane guide channel system – noise & vibration dampening

- Hydrodynamic support via high-volume oil flow into channels

- Double pusher, space-saving design

- Bearing block steady rest – super rigid design mounted to base of the machine to provide maximum support of bar stock and pusher

- Separate floor-mounted electric cabinet isolates electronics from vibration

- (1) Guide channel set to be chosen by customer. Several sizes to choose from, each handling a specific stock range. See table above (spindle liner required if channel set is not lathe’s max capacity)

- (1) Universal telescoping front nose and (1) nylon nose I.D. liner specific to pusher

- (1) O.D. bar stock collet to be chosen by customer (specific collet needed for each stock diameter)

- Swiss headstock synchronization device

- Automatic remnant retraction, self-centering gripper

- Custom lathe cable and interface plugs

- Polyurethane bushing blocks (2 pieces)

- Spindle tube nose assembly – available in 7mm, 10mm

| Technical Specifications | |

|---|---|

| Bar diameter | 2mm – 23mm (0.078” – 0.905”) |

| Bar Length | 1000mm – 3800mm (39.4” – 12’5”) |

| Magazine Rack Capacity | 177.8mm (7”) |

| Maximum Remnant Length | 420mm (16.5”) |

| Bar Loading Cycle Time | Approx. 25 sec for 12’ bars |

| Feed Force (Pusher Torque) | Max 300 N, adjustable |

| Forward Feed Rate | 300mm/sec (710in/min) max, adjustable |

| Return Feed Rate | 601mm/sec (1420in/min) max, adjustable |

| Power Consumption | 1.5 kW/2 kVA |

| Operating Voltage | 230-400 V/60 Hz – 3 phase |

| Control Voltage | 24V DC |

| Oil Capacity | 50 liters (13.2 gallons) |

| Oil Viscosity | ISO 64 cST – Machine oil ISO BG32 – Air oil |

| Compressed Air Supply | 6 bar (90 psi) |

| Compressed Air Consumption | ~3 liters per loading cycle |

| Machine Weight (w/out Oil) | 749 kg (1650 lbs) |

| Material Straightness Specification | 0.007” TIR/foot of material (V blocks, 6’ equidistant) |

| Guide Channel Sets | Pusher Diameter | Minimum Bar Size | Maximum Bar Size |

Max. Bar Size With Front Remnant Expulsion * |

|---|---|---|---|---|

| Ø 5mm | 5mm | 2mm (0.078”) | 4mm (0.157″) | 5mm (0.196″) |

| Ø 7mm | 7mm | 2mm (0.078″) | 6.4mm (0.250″) | 7mm (0.275″) |

| Ø 10mm | 10mm | 3mm (0.118″) | 8mm (0.315″) | 10mm (0.393″) |

| Ø 12mm | 12mm | 2.4mm (0.094″) | 10.4mm (0.409″) | 12mm (0.472″) |

| Ø 13mm | 13mm | 3mm (0.118″) | 11.1mm (0.437″) | 13mm (0.511″) |

| Ø 15mm | 15mm | 5mm (0.196″) | 13mm (0.511″) | 15mm (0.590″) |

| Ø 18mm | 18mm | 6.5mm (0.255″) | 16mm (0.629″) | 18mm (0.708″) |

| Ø 20mm | 20mm | 8mm (0.315″) | 18mm (0.708″) | 20mm (0.787″) |

| Ø 22mm | 22mm | 8mm (0.315″) | 20mm (0.787″) | 22mm (0.866″) |

| Ø 23mm | 23mm | 10mm (0.393”) | 20mm (0.787”) | 23mm (0.905”) |