Edge Technologies’ Vortex AF Series is an extremely effective water-soluble coolant mist collector & filtration system. It is specifically designed for machine tools performing wet machining operations.

The Vortex AF coolant mist collector is the perfect synthesis of advanced centrifugal separation and HEPA air filtration, achieving high air purification efficiency with minimum maintenance and low cost.

CONTACT VORTEX SALES:

(314) 810-3861

Learn about the Vortex Mist Collection System:

Effectively Removes

- Water-soluble coolant mist

- Fog

- Aerosols

- Smoke

Why the Vortex Coolant Mist Collector?

- Highly effective 3-stage centrifugal-impaction filtration

- 99.97% filtering efficiency as measured by MPPS method using a final stage E12 HEPA filter

- Minimal maintenance-filter changing

- Compact mist collector design

- Recycles water-soluble coolant mist

- Low power consumption

Features: Vortex AF Series

- Easy access for 1st-Stage filter removal

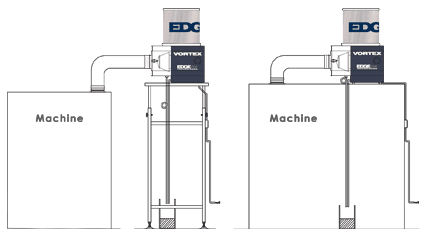

- Choice of mounts: machine, stand, or ceiling

- 220v 3-phase power

- Airflow capacities from 475 to 1700 CFM

- Designed for working envelopes from <215 to 1130 cubic feet

- Choice of independent or machine power supply

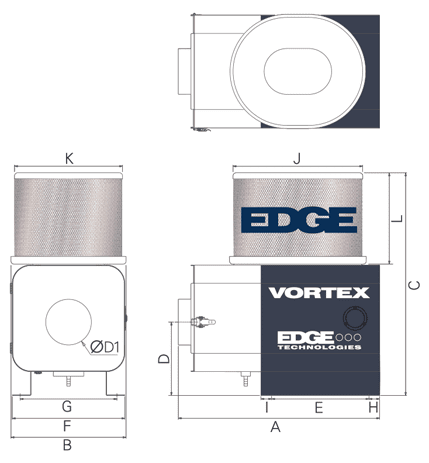

Dimensions

Mounting Configurations

Vortex AF Series

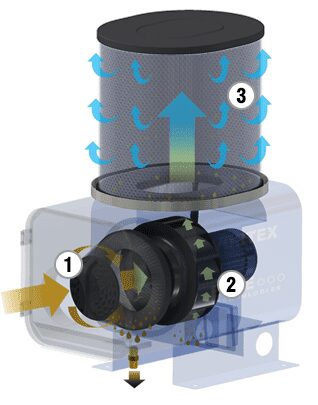

Vortex Mist Collector Air Flow

1 – 1st-Stage Separation: The coolant mist air-stream initially collides with the fish scale profile, coalescing the mist into larger droplets. Then, through a wind-shear effect with the 70-degree, self-draining mesh filter, smoke & particles greater than 2 microns (2µm) are captured.

The 1st-Stage Filter is a patented 70-degree conical mesh filter featuring an innovative fish scale profile on the leading edge and a synthetic mesh overlay. A built in handle makes maintenance easy on this washable element.

Coolant mist collection drain outlet: Precipitated droplets are collected and returned to the coolant tank.

2 – 2nd-Stage Separation: The efficient centrifugal impeller fan located in the 2nd chamber provides highly efficient system airflow at low running noise continuing the separation process.

3 – 3rd-Stage E12 HEPA After-Filter: Finishes the air purification to a 99.97% filtering efficiency by capturing all particles greater than .3 microns (.3µm) before releasing the purified air back into the plant.

| Model Dimensions [mm] (See diagram above) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | A | B | C | D | E | F | G | H | I | J | K | L |

| AF-10P | 24.2″ (615) | 14.9″ (379) | 32.7″ (831) | 10.3″ (236) | 11.8″ (300) | 13.2″ (335) | 11.1″ (283) | 1.0″ (25) | 1.0″ (25) | 16.7″ (426) | 14″ (355) | 16.2″ (413) |

| AF-20P | 25.6″ (652) | 14.9″ (379) | 33.5″ (851) | 9.2″ (234) | 12.6″ (320) | 13.8″ (350) | 11.7″ (298) | 1.0″ (25) | 1.0″ (25) | 16.7″ (426) | 14″ (355) | 16.2″ (413) |

| AF-30P | 30.1″ (765) | 17″ (432) | 35.7″ (908) | 11.8″(299) | 15.3″ (388) | 16.5″ (420) | 14.5″ (368) | 1.0″ (25) | 1.0″ (25) | 19.4″ (492)) | 16.1″ (408) | 16.2″ (413) |

| AF-40PL | 31.2″ (792) | 19.3″ (490) | 45.4″ (1153) | 12.4″ (316) | 15.3″ (388) | 18.9″ (480) | 16.8″(428) | 1.3″(33.5) | 1.3″ (33.5) | 21.2″ (540) | 16.9″ (430) | 24.1″ (613) |

| Technical Data | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Suitable Cabin Size (CF Cubic Feet) | Air Flow (PER MIN) | Static Pressure | Sound Level (db) A | Power Supply | Power Consumption | Weight | Inlet Port |

| AF-10P | <215 CF

(<6 CM) | 475 CF

(13.5 CM) | .152 PSI

(1.05 kPa) | 68 | 220V / 60Hz | .27 HP

(0.2 kW) | 93 lb

(42.1 kg) | 6”

(150 mm) |

| AF-20P | <425 CF

(<12 CM) | 725 CF

(20.5 CM) | .200 PSI

(1.38 kPa) | 73 | 220V / 60Hz | .53 HP

(0.4 kW) | 104 lb

(47.1 kg) | 6”

(150 mm) |

| AF-30P | <850 CF

(< 24 CM) | 1150 CF

(32.5 CM) | .239 PSI

(1.65 kPa) | 74 | 220V / 60Hz | 1.00 HP

(0.75 kW) | 143 lb

(64.8 kg) | 8”

(200 mm) |

| AF-40PL | < 1130 CF

(< 32 CM) | 1700 CF

(48.5 CM) | .282 PSI

(1.95 kPa) | 75 | 220V / 60Hz | 1.54 HP

(1.15 kW) | 176 lb

(79.8 kg) | 10”

(250 mm) |