Features: Patriot 338 Bar Feeder

- Bar diameter capacity: 3mm to 42mm (0.118” to 1.653”)

- Automatic loading magazine – 12 linear inches of Rack Capacity

- Polyurethane quick-change guide channel – noise & vibration dampening

- Hydrodynamic support via high-volume oil flow into channels

- Dual anti-vibration devices — one internal to the bar feeder, the other mounted between the telescopic nose and the lathe headstock

- (1) Guide channel set to be chosen by customer. Several sizes to choose from, each handling a specific stock range. See table above (spindle liner required if channel set is not lathe’s max capacity)

- (1) Standard telescoping front nose matched to the guide channel set

- (1) O.D. bar stock collet to be chosen by customer (specific collet needed for each stock diameter)

- (1) Bushing block for outboard anti-vibration device to be chosen by customer based on bar diameter

- Swiss headstock synchronization device & adaptation kit

- Custom lathe cable and interface plugs

- Air knife with flow control valve

- Axial shift device with safety switches

| Technical Specifications | |

|---|---|

| Bar Diameter | 3mm – 42mm (0.118” – 1.653”) |

| Bar Length | 1000mm – 3800mm (39.4” – 12’5”) |

| Magazine Rack Capacity | 304mm (12”) |

| Maximum Remnant Length | 406mm (16”) |

| Bar Loading Cycle Time | Approx. 30 sec for 12’ bars |

| Feed Force (Pusher Torque) | Max 450 N, adjustable |

| Forward Feed Rate | 593mm/sec (1400 in/min) max, adjustable |

| Return Feed Rate | 1000mm/sec (2360 in/min) max, adjustable |

| Power Consumption | 1.5 kW/2 kVA |

| Operating Voltage | 230 V/60 Hz – 3 phase |

| Control Voltage | 24V DC |

| Oil Capacity | 57 liters (15 gallons) |

| Oil Viscosity | ISO 100 cST – Machine oil ISO BG32 – Air oil |

| Compressed Air Supply | 6 bar (90 psi) |

| Compressed Air Consumption | ~8 liters per loading cycle |

| Machine Weight (w/out Oil) | 1130 kg (2500 lbs) |

| Material Straightness Specification | 0.007” TIR/foot of material (V blocks, 6’ equidistant) |

| Guide Channel Sets | Pusher Diameter | Minimum Bar Size | Maximum Bar Size | Max. Bar Size With Front Remnant Expulsion * |

|---|---|---|---|---|

| Ø 13 mm | 12.5 mm | 3 mm (.118”) | 10 mm (.393”) | 12 mm (.472”) |

| Ø 17 mm | 16.5 mm | 5 mm (.196”) | 15 mm (.591”) | 16 mm (.630”) |

| Ø 21 mm | 20.5 mm | 8 mm (.315”) | 19 mm (.750”) | 20 mm (.787”) |

| Ø 26 mm | 25.0 mm | 8 mm (.315”) | 22.2 mm (.875”) | 25 mm (.984”) |

| Ø 28 mm | 27.5 mm | 10 mm (.393”) | 25.4 mm (1.000”) | 27 mm (1.062”) |

| Ø 33 mm | 32.5 mm | 10 mm (.393”) | 28.5 mm (1.125”) | 32 mm (1.259”) |

| Ø 36 mm | 34 or 35.5 mm | 12.7 mm (.500”) | 32 mm (1.260”) | 35 mm (1.377”) |

| Ø 39 mm | 38.0 mm | 15.8 mm (.625”) | 35.0 mm (1.377”) | 38 mm (1.500”) |

| Ø 43 mm | 42.5 mm | 19 mm (0.750″) | 38 mm (1.500″) | 42 mm (1.653″) |

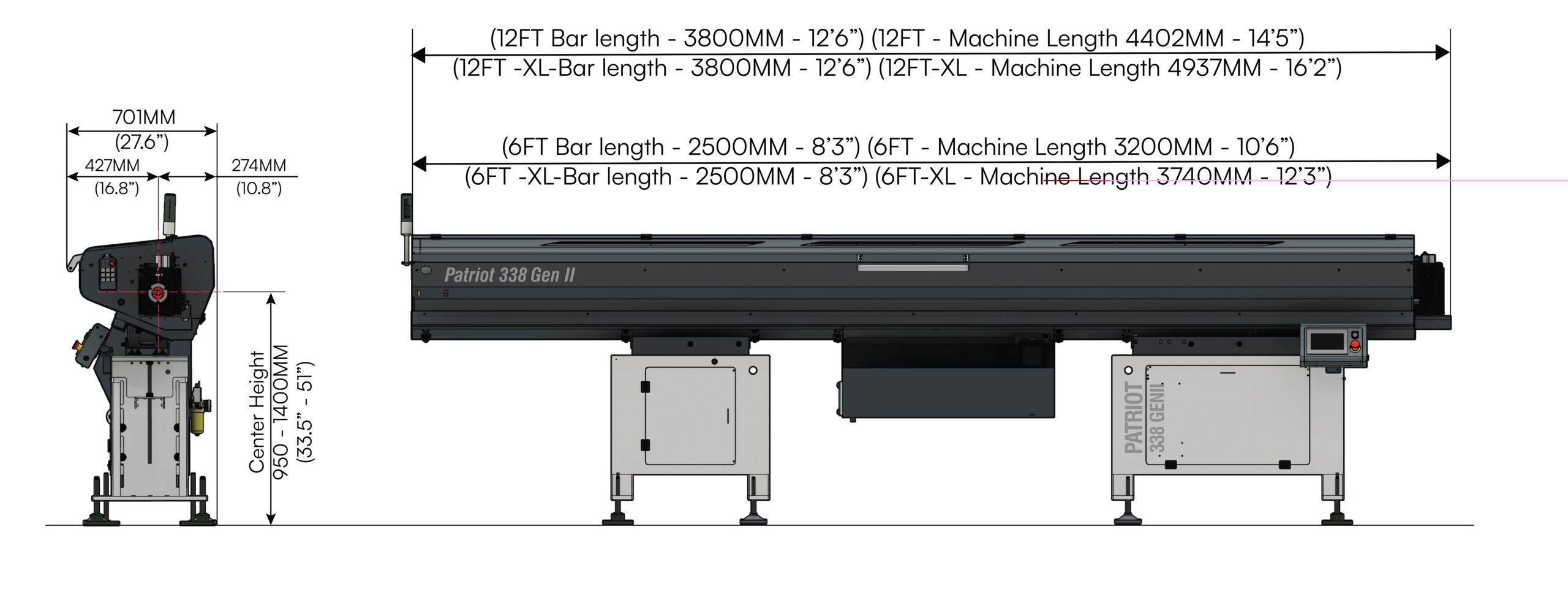

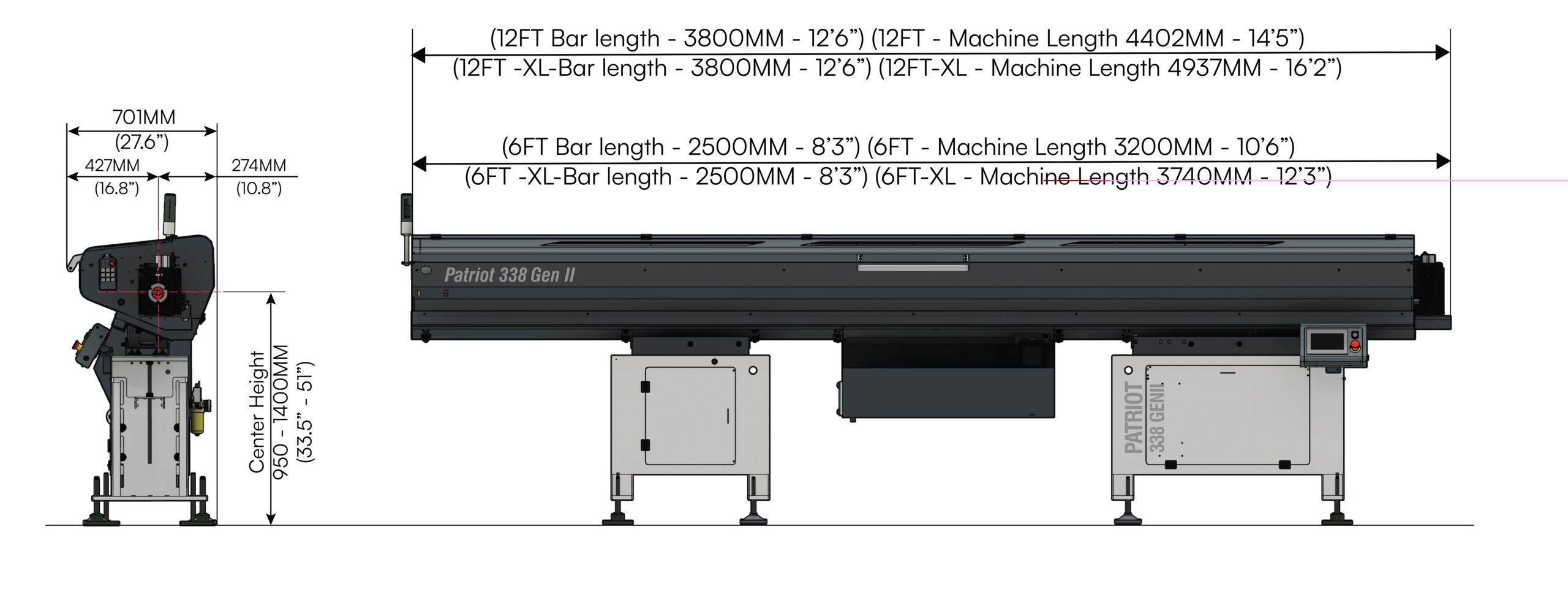

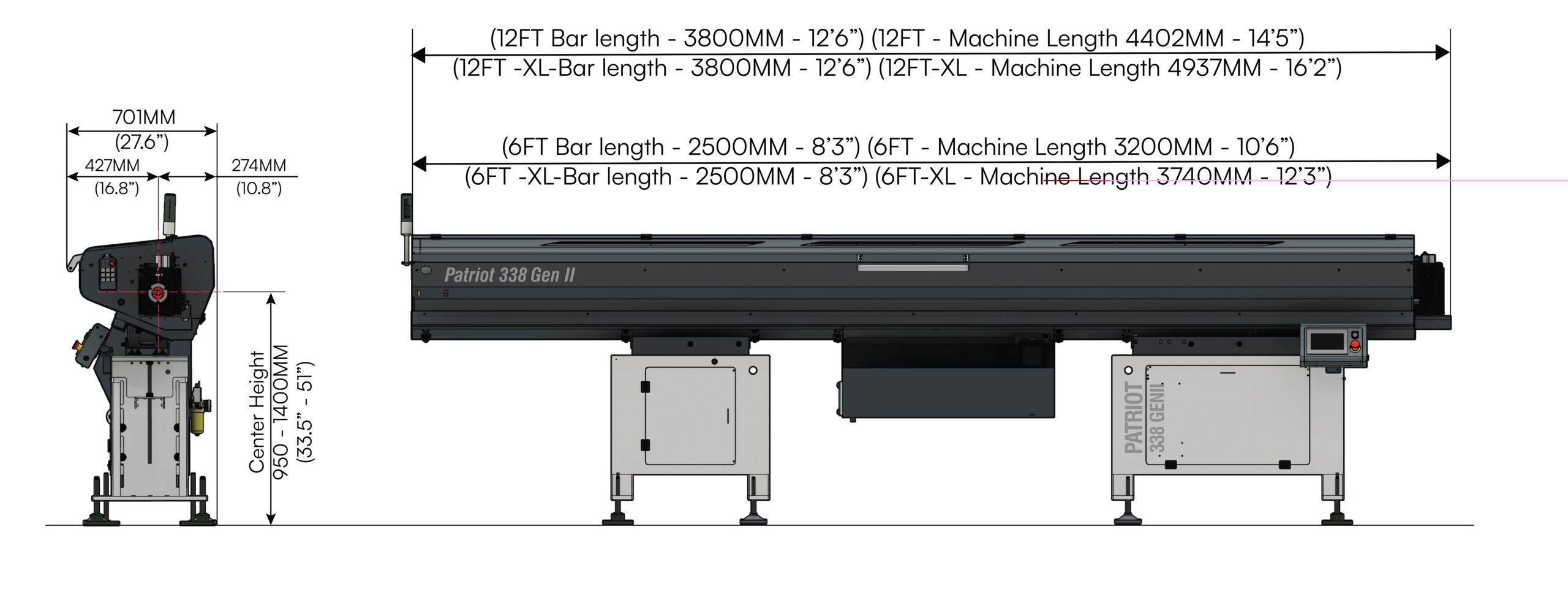

The Edge Technologies Patriot 338, available in 6′ or 12′ configurations, is designed specifically for the U.S. marketplace. These magazine type bar feeders are designed for automatically feeding round, square, and hexagonal bar stock in fixed headstock and Swiss CNC lathes with a stock diameter range of 3-38mm and in lengths up to 12 feet.

Features: Patriot 338 Bar Feeder

- Bar diameter capacity: 3mm to 42mm (0.118” to 1.653”)

- Automatic loading magazine – 12 linear inches of Rack Capacity

- Polyurethane quick-change guide channel – noise & vibration dampening

- Hydrodynamic support via high-volume oil flow into channels

- Dual anti-vibration devices — one internal to the bar feeder, the other mounted between the telescopic nose and the lathe headstock

- (1) Guide channel set to be chosen by customer. Several sizes to choose from, each handling a specific stock range. See table above (spindle liner required if channel set is not lathe’s max capacity)

- (1) Standard telescoping front nose matched to the guide channel set

- (1) O.D. bar stock collet to be chosen by customer (specific collet needed for each stock diameter)

- (1) Bushing block for outboard anti-vibration device to be chosen by customer based on bar diameter

- Swiss headstock synchronization device & adaptation kit

- Custom lathe cable and interface plugs

- Air knife with flow control valve

- Axial shift device with safety switches

| Technical Specifications | |

|---|---|

| Bar Diameter | 3mm – 42mm (0.118” – 1.653”) |

| Bar Length | 1000mm – 3800mm (39.4” – 12’5”) |

| Magazine Rack Capacity | 304mm (12”) |

| Maximum Remnant Length | 406mm (16”) |

| Bar Loading Cycle Time | Approx. 30 sec for 12’ bars |

| Feed Force (Pusher Torque) | Max 450 N, adjustable |

| Forward Feed Rate | 593mm/sec (1400 in/min) max, adjustable |

| Return Feed Rate | 1000mm/sec (2360 in/min) max, adjustable |

| Power Consumption | 1.5 kW/2 kVA |

| Operating Voltage | 230 V/60 Hz – 3 phase |

| Control Voltage | 24V DC |

| Oil Capacity | 57 liters (15 gallons) |

| Oil Viscosity | ISO 100 cST – Machine oil ISO BG32 – Air oil |

| Compressed Air Supply | 6 bar (90 psi) |

| Compressed Air Consumption | ~8 liters per loading cycle |

| Machine Weight (w/out Oil) | 1130 kg (2500 lbs) |

| Material Straightness Specification | 0.007” TIR/foot of material (V blocks, 6’ equidistant) |

| Guide Channel Sets | Pusher Diameter | Minimum Bar Size | Maximum Bar Size | Max. Bar Size With Front Remnant Expulsion * |

|---|---|---|---|---|

| Ø 13 mm | 12.5 mm | 3 mm (.118”) | 10 mm (.393”) | 12 mm (.472”) |

| Ø 17 mm | 16.5 mm | 5 mm (.196”) | 15 mm (.591”) | 16 mm (.630”) |

| Ø 21 mm | 20.5 mm | 8 mm (.315”) | 19 mm (.750”) | 20 mm (.787”) |

| Ø 26 mm | 25.0 mm | 8 mm (.315”) | 22.2 mm (.875”) | 25 mm (.984”) |

| Ø 28 mm | 27.5 mm | 10 mm (.393”) | 25.4 mm (1.000”) | 27 mm (1.062”) |

| Ø 33 mm | 32.5 mm | 10 mm (.393”) | 28.5 mm (1.125”) | 32 mm (1.259”) |

| Ø 36 mm | 34 or 35.5 mm | 12.7 mm (.500”) | 32 mm (1.260”) | 35 mm (1.377”) |

| Ø 39 mm | 38.0 mm | 15.8 mm (.625”) | 35.0 mm (1.377”) | 38 mm (1.500”) |

| Ø 43 mm | 42.5 mm | 19 mm (0.750″) | 38 mm (1.500″) | 42 mm (1.653″) |

Patriot 338 Bar Feeder

The Edge Technologies Patriot 338, available in 6′ or 12′ configurations, is designed specifically for the U.S. marketplace. These magazine type bar feeders are designed for automatically feeding round, square, and hexagonal bar stock in fixed headstock and Swiss CNC lathes with a stock diameter range of 3-38mm and in lengths up to 12 feet.

Features: Patriot 338 Bar Feeder

- Bar diameter capacity: 3mm to 42mm (0.118” to 1.653”)

- Automatic loading magazine – 12 linear inches of Rack Capacity

- Polyurethane quick-change guide channel – noise & vibration dampening

- Hydrodynamic support via high-volume oil flow into channels

- Dual anti-vibration devices — one internal to the bar feeder, the other mounted between the telescopic nose and the lathe headstock

- (1) Guide channel set to be chosen by customer. Several sizes to choose from, each handling a specific stock range. See table above (spindle liner required if channel set is not lathe’s max capacity)

- (1) Standard telescoping front nose matched to the guide channel set

- (1) O.D. bar stock collet to be chosen by customer (specific collet needed for each stock diameter)

- (1) Bushing block for outboard anti-vibration device to be chosen by customer based on bar diameter

- Swiss headstock synchronization device & adaptation kit

- Custom lathe cable and interface plugs

- Air knife with flow control valve

- Axial shift device with safety switches

| Technical Specifications | |

|---|---|

| Bar Diameter | 3mm – 42mm (0.118” – 1.653”) |

| Bar Length | 1000mm – 3800mm (39.4” – 12’5”) |

| Magazine Rack Capacity | 304mm (12”) |

| Maximum Remnant Length | 406mm (16”) |

| Bar Loading Cycle Time | Approx. 30 sec for 12’ bars |

| Feed Force (Pusher Torque) | Max 450 N, adjustable |

| Forward Feed Rate | 593mm/sec (1400 in/min) max, adjustable |

| Return Feed Rate | 1000mm/sec (2360 in/min) max, adjustable |

| Power Consumption | 1.5 kW/2 kVA |

| Operating Voltage | 230 V/60 Hz – 3 phase |

| Control Voltage | 24V DC |

| Oil Capacity | 57 liters (15 gallons) |

| Oil Viscosity | ISO 100 cST – Machine oil ISO BG32 – Air oil |

| Compressed Air Supply | 6 bar (90 psi) |

| Compressed Air Consumption | ~8 liters per loading cycle |

| Machine Weight (w/out Oil) | 1130 kg (2500 lbs) |

| Material Straightness Specification | 0.007” TIR/foot of material (V blocks, 6’ equidistant) |

| Guide Channel Sets | Pusher Diameter | Minimum Bar Size | Maximum Bar Size | Max. Bar Size With Front Remnant Expulsion * |

|---|---|---|---|---|

| Ø 13 mm | 12.5 mm | 3 mm (.118”) | 10 mm (.393”) | 12 mm (.472”) |

| Ø 17 mm | 16.5 mm | 5 mm (.196”) | 15 mm (.591”) | 16 mm (.630”) |

| Ø 21 mm | 20.5 mm | 8 mm (.315”) | 19 mm (.750”) | 20 mm (.787”) |

| Ø 26 mm | 25.0 mm | 8 mm (.315”) | 22.2 mm (.875”) | 25 mm (.984”) |

| Ø 28 mm | 27.5 mm | 10 mm (.393”) | 25.4 mm (1.000”) | 27 mm (1.062”) |

| Ø 33 mm | 32.5 mm | 10 mm (.393”) | 28.5 mm (1.125”) | 32 mm (1.259”) |

| Ø 36 mm | 34 or 35.5 mm | 12.7 mm (.500”) | 32 mm (1.260”) | 35 mm (1.377”) |

| Ø 39 mm | 38.0 mm | 15.8 mm (.625”) | 35.0 mm (1.377”) | 38 mm (1.500”) |

| Ø 43 mm | 42.5 mm | 19 mm (0.750″) | 38 mm (1.500″) | 42 mm (1.653″) |