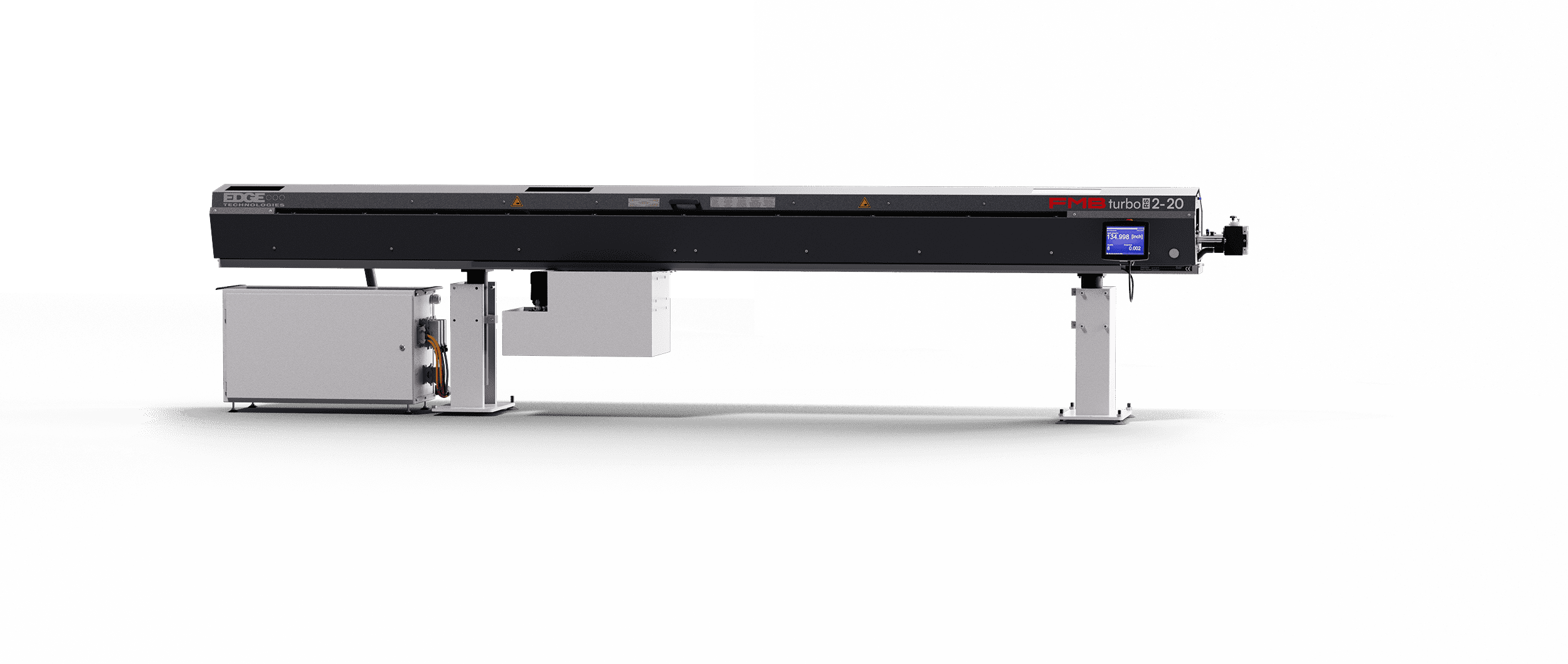

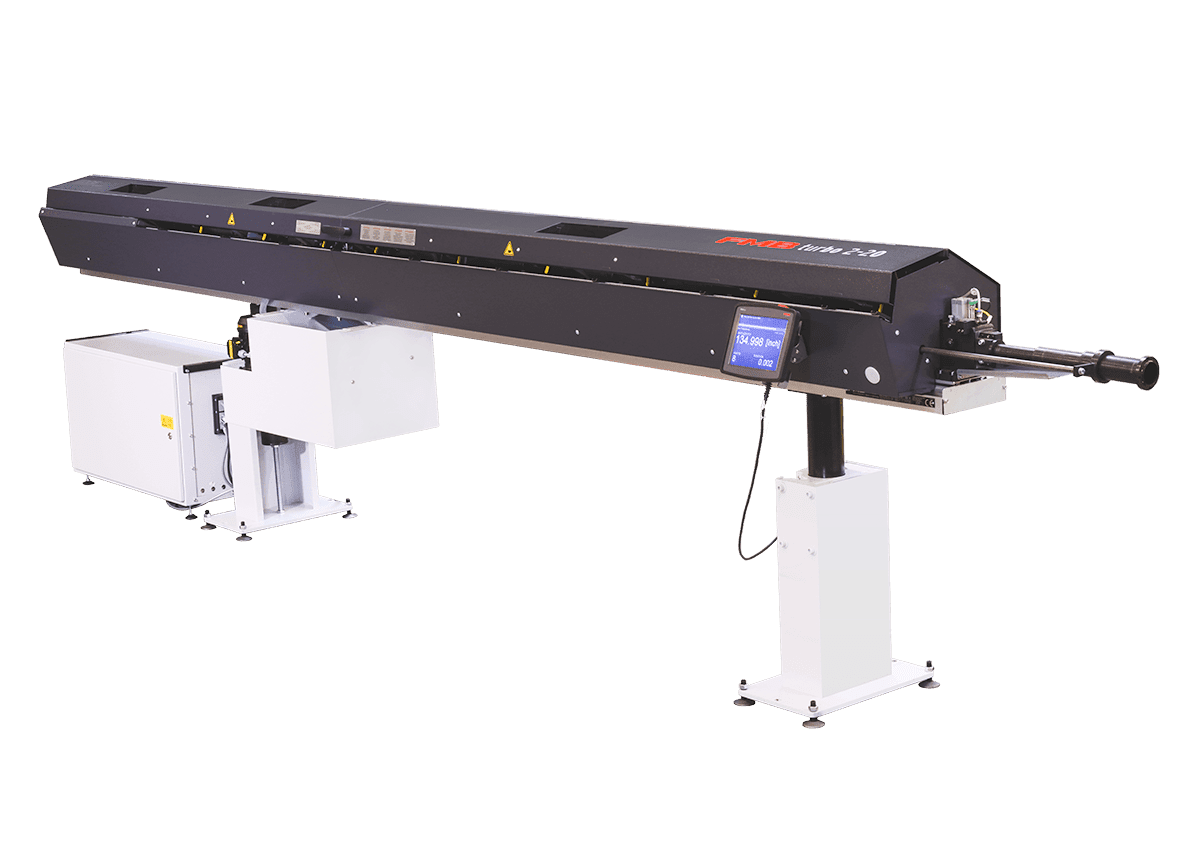

FMB Turbo RS 2-20

The FMB Turbo RS 2-20 is your solution for longer run productions on smaller parts! An outboard steady device controls bar whip between the barfeed and lathe spindle, and works great with profiled material. Extruded aluminium provides a solid base for the loading magazine backbone. This rigid structure forms the guide channel sets, giving them the widest range in the industry. You can expect precision and accuracy in a compact design.

The Turbo 2-20 has always led the way in bar feeding rigidity. Now it comes with RS technology, which further increases performance on the same tried-and-true design.

RS Feature

Instead of the telescopic nose device that traditionally connects the machine tool and bar feeder, the bar feeder uses RS technology. A steady-rest mounts directly to the back of machine tool’s headstock, providing material support at the back of the spindle, while an extension tube or guide module (what could be considered a sliding spindle liner) is internal to the bar feeder. As raw material travels, the integrated and oiled sliding guide module and moving steady rest provide superior bar pusher and stock support in the transition zone between the bar feeder and lathe spindle.