Why Is My Remnant So Long? Part 4

This is part 4 in my ongoing series of videos describing the remnant length of bar fed machining applications. In this video we look at fixed headstock lathes and talk about remnant length in sub-spindle pulling applications as opposed to feeding to a stop. Please watch Parts 1-3 for details regarding sliding head applications.

Here’s the link to Part 1

In this video, Regional Service Manager Brian Grisez demonstrates how to test the rotation direction of a three phase pump in a bar feeder using a zip...

In this instructional video, Regional Service Manager Brian Grisez documents the process for setting Front Limit Posiotion and First Insert Position on Edge and FMB bar...

Are you asking this question: Why is my remnant so long, specifically related to bar feeder remnants in Swiss- or sliding headstock applications. In this instructional...

In this video, Brian Grisez describes how to successfully calculate the installation position for a bar loader relative to a lathe, and all the variables and...

In this video, Regional Service Manager Brian Grisez demonstrates how to test a synchronization device on a bar loader used in Swiss-type or sliding headstock...

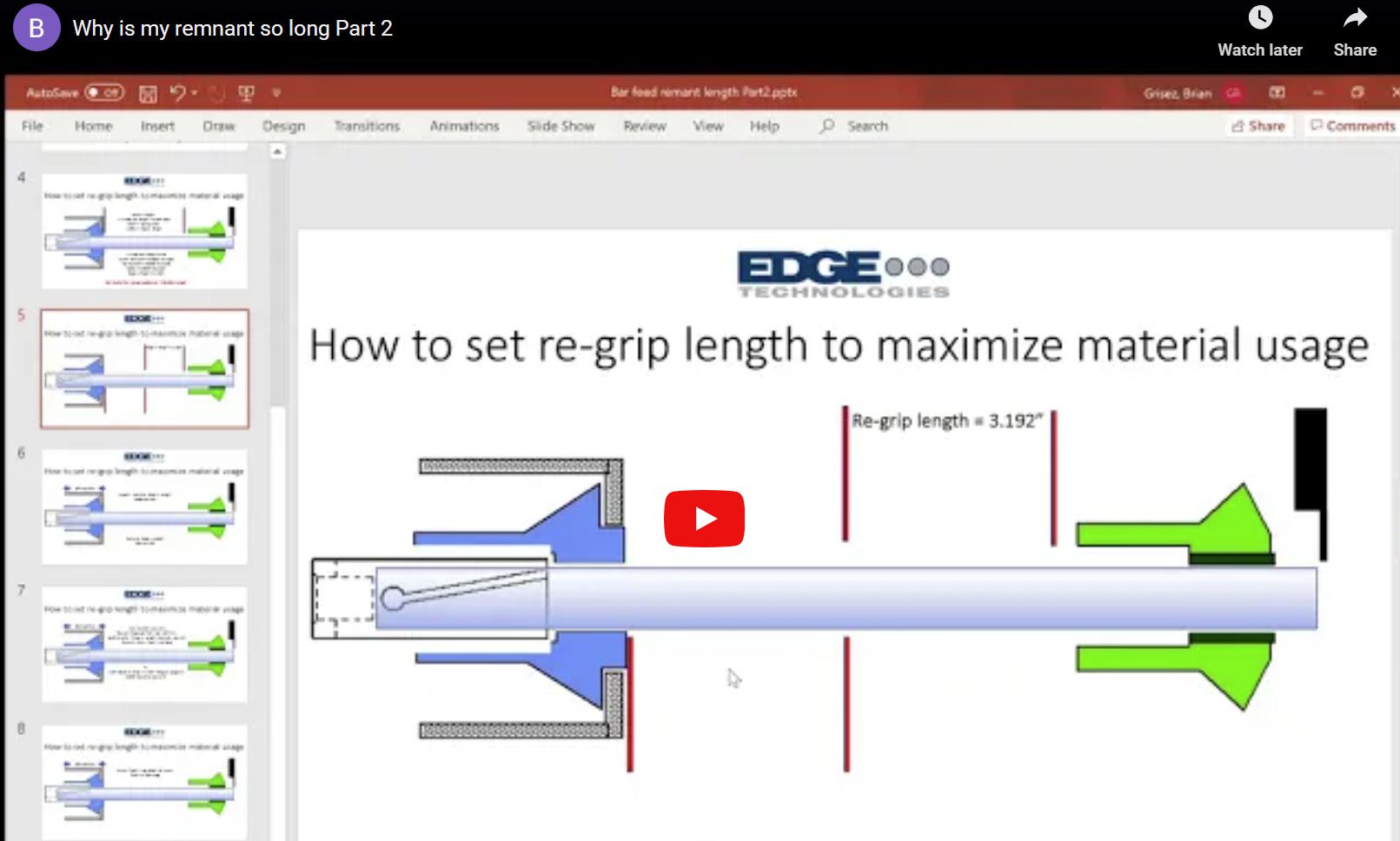

Part 2 of an instructional video series describing remnant length related to bar fed Swiss machine applications. If you haven't watched Part 1, start with that....

Part 3 of an instructional video series describing remnant length related to bar fed Swiss machine applications. If you haven't watched Part 1 and 2, start with those....

In this video, Regional Service Manager Brian Grisez gives a live demonstration of an Edge Technologies Flex Lift machine that has been customized to load 3' length bar...