Why 2nd End of Bar May Be Exactly What You Need for Your Applications Running Longer Parts

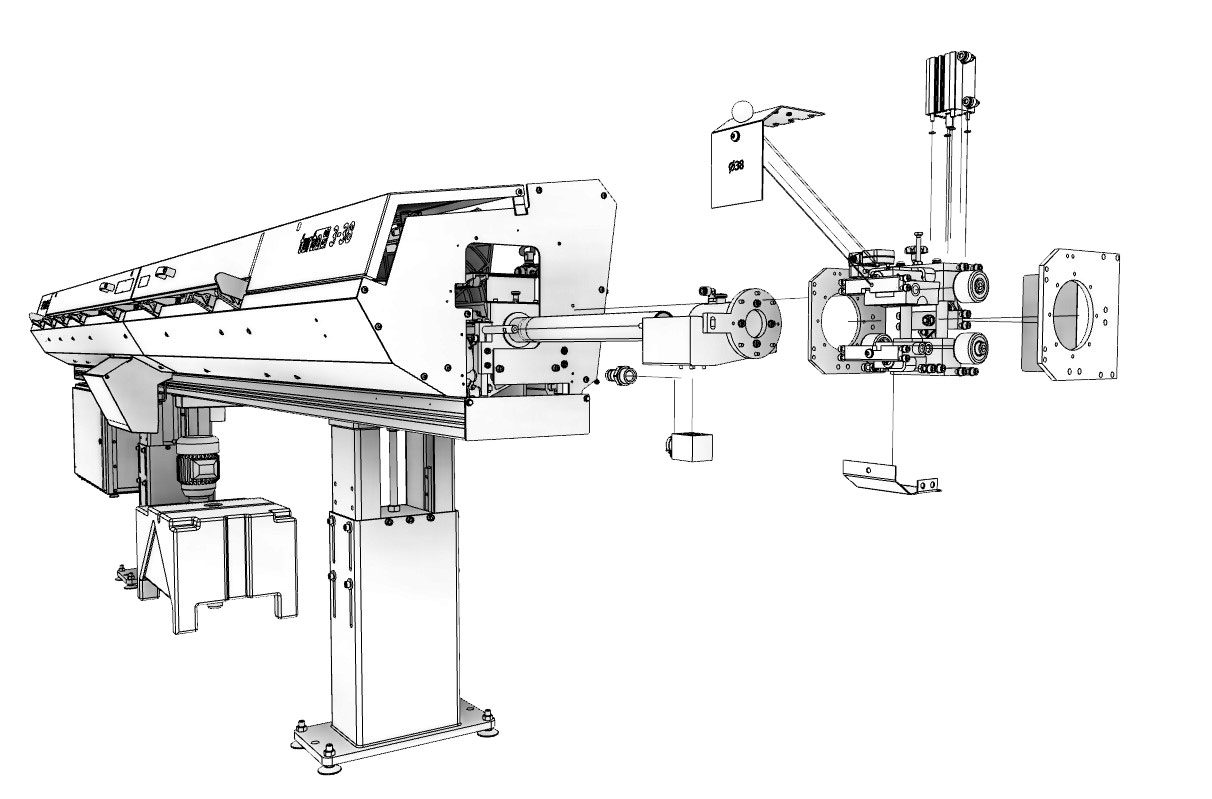

Since 2025, we’ve seen an increase in shaft work – more shops making longer parts. One function that can deliver a lot of value for this type of work is 2nd End of Bar, an advanced customization that Edge Technologies can provide on our bar feeders.

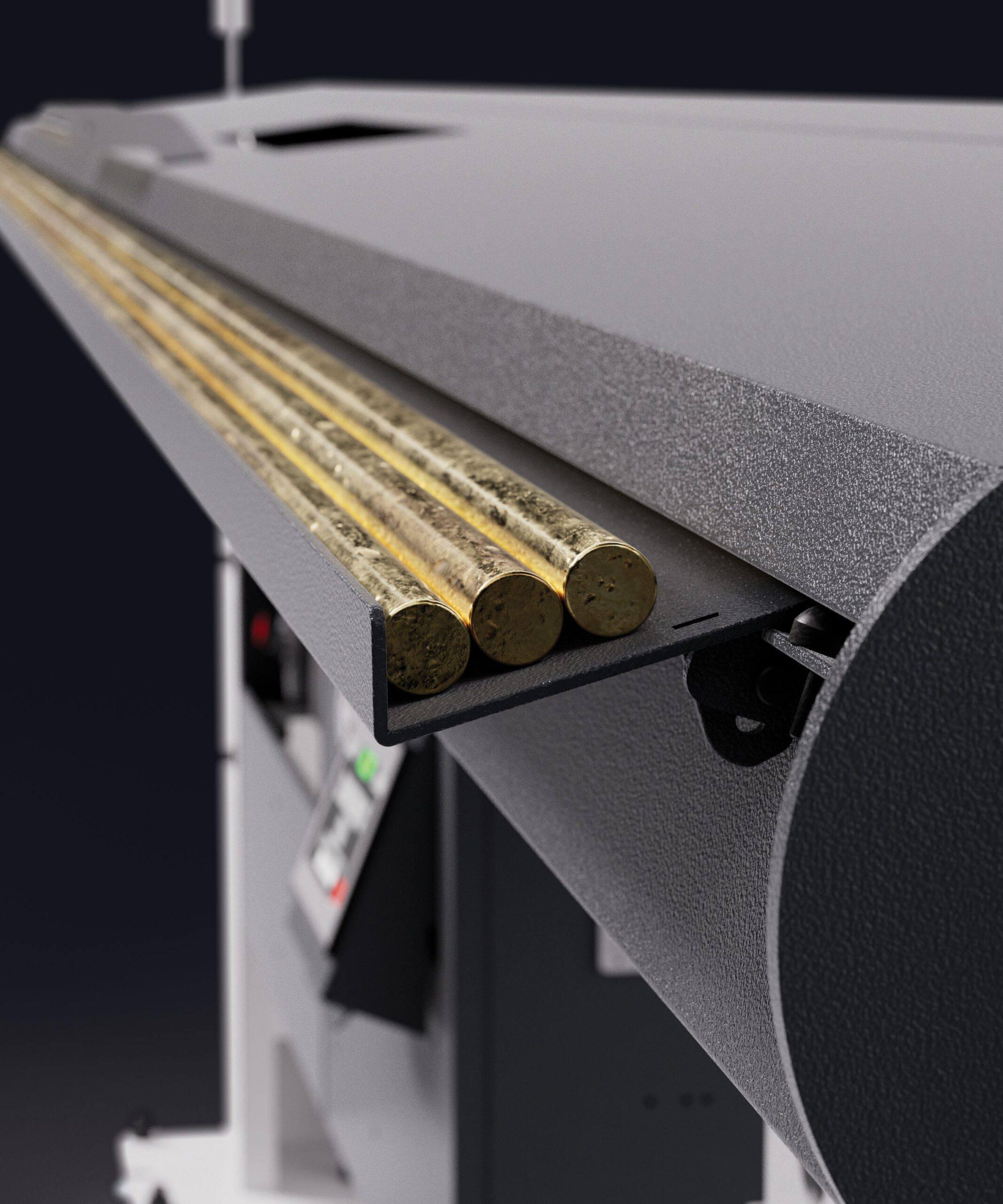

Let’s say you’re running an application: turning 12’ bars to produce 18” parts.

But this is part of a family that includes 10” and 7” parts as well.

You know that the 12’ bar can only produce seven of the 18” parts (because you have to account for the cutoff tool width, facing width, and regrip length, etc.). This leaves you a remnant that’s over 12” long. In other words, longer than ideal.

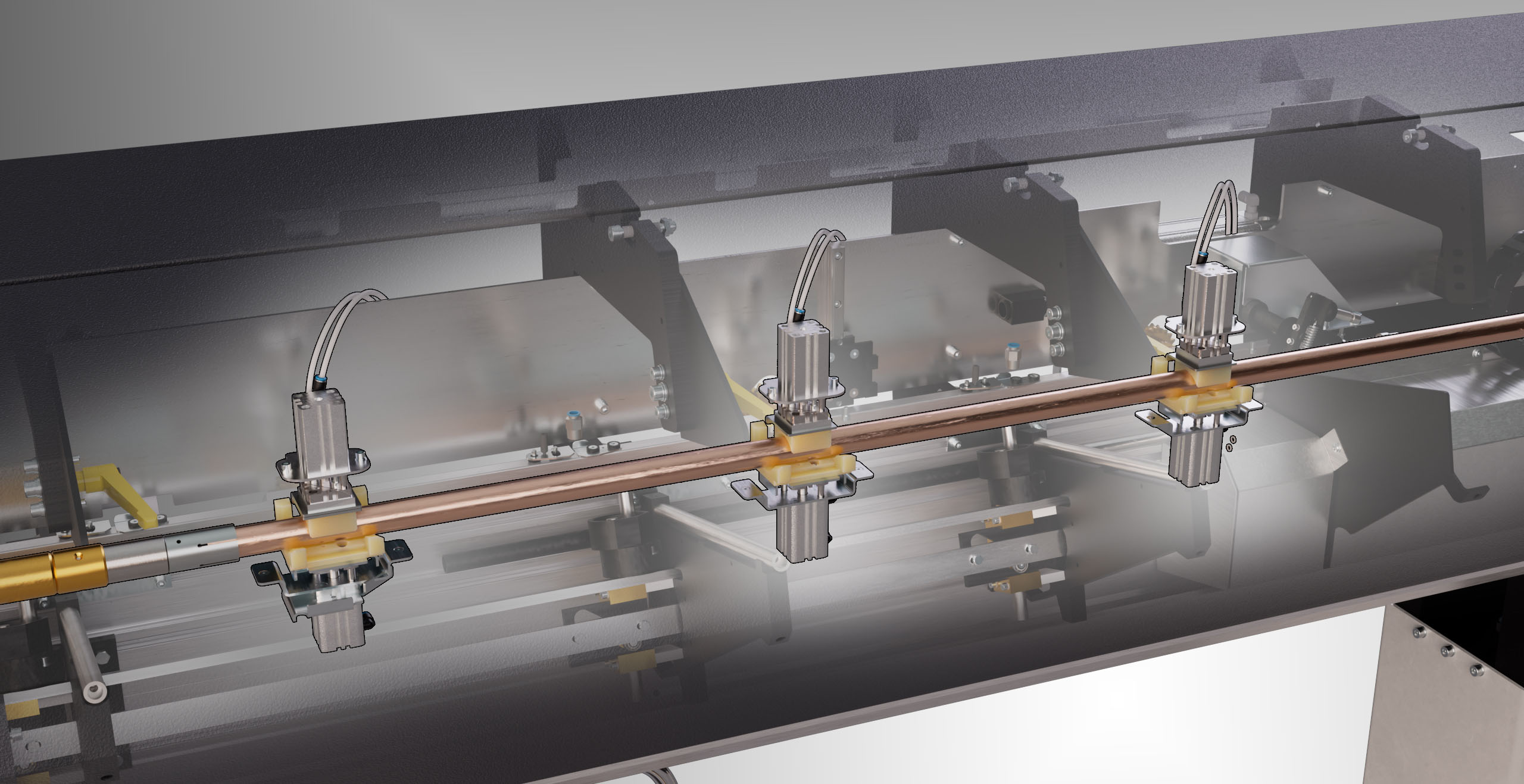

This is where 2nd End of Bar protocol comes in. The 2nd End of Bar recognizes the family of parts (the 10” and 7”) and understands that one of these smaller parts needs to be made anyway. So the lathe pumps out those seven 18” parts, then the bar feeder changes EOB signal to run the 7” part from the family.

2nd End of Bar protocol is an advanced customization that Edge Technologies can provide on our bar feeders. The 2nd End of Bar recognizes a family of parts and understands that one of these smaller parts needs to be made anyway. So the lathe pumps out those seven 18” parts, then the bar feeder changes EOB signal to run the 7” part from the family.

This keeps your overall production lead time down while reducing your remnant. And, if you’re working with expensive high-end material like stainless, titanium, brass, 2nd End of Bar can spell real savings, because you’re making the most of each bar.

Sound like a protocol you need? Edge Technologies can guide you. Please do not hesitate to contact us.