4 Applications Perfect for Slug Loading

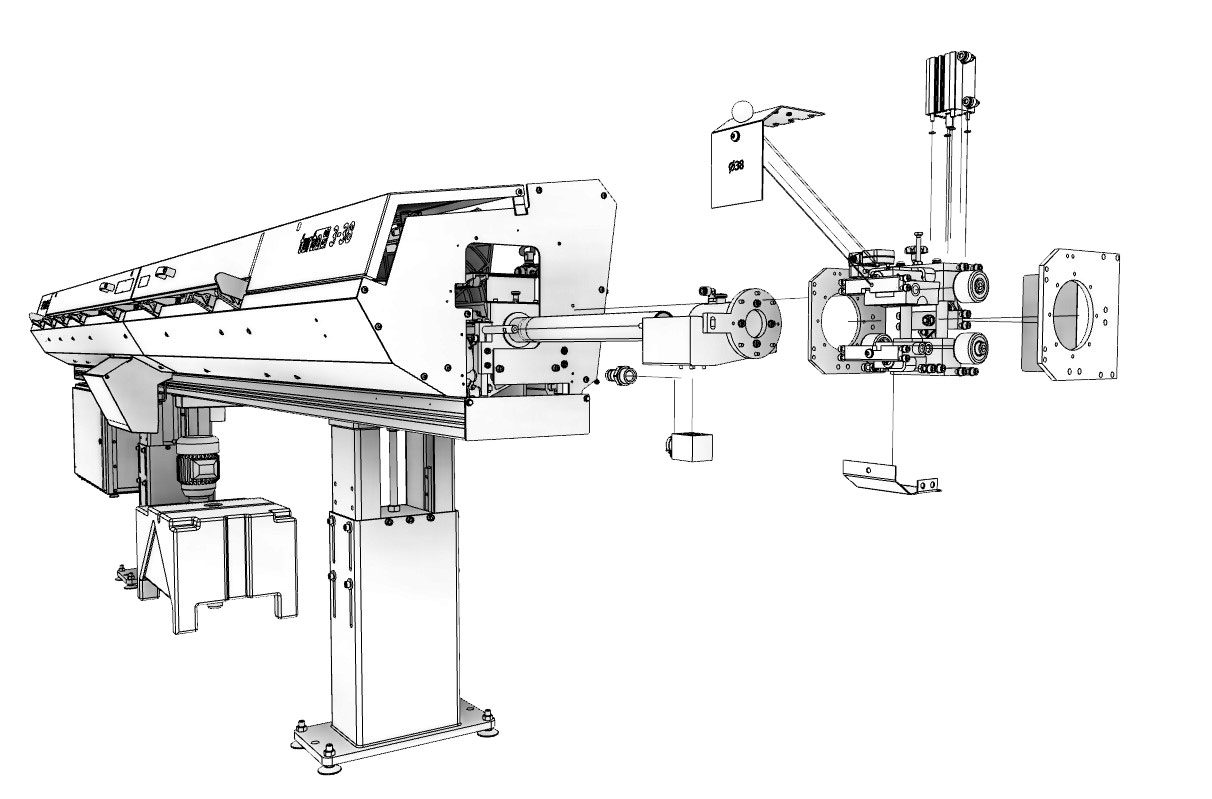

Short loaders, or spindle-length loaders, can be a very cost-effective solution. They occupy minimal floor space, don’t need to be attached to the bar stock, and don’t demand bar end preparation. Because the entire bar stock is contained within the lathe headstock, they eliminate nearly all RPM restrictions. Short bar feeders also shine in handling profiled materials or non-perfectly straight bars. When coupled with a spindle liner and customized workholding, these loaders can efficiently process various extruded shapes, such as square and rectangular bars. This versatility makes a short bar feeder suitable for unattended machining and lights out production.

Another technique that is special to short loaders, and helps to cement their value, is slug loading.

What Is Slug Loading?

Some people refer to it as hand-chuck mode or shaft loading.

Where a bar feed involves a long metal bar being fed into a machine for shaping or sizing multiple parts, a slug load involves a single, solid material piece being machined into a specific shape or size. You might think of it kind of like firing a rifle. You put in the shell, fire, pull back, get rid of the shell, then add a new shell in. In the same way, you machine a single piece, and then the next piece drops in to get machined.

The rule for slug loading is: One bar equals one part.

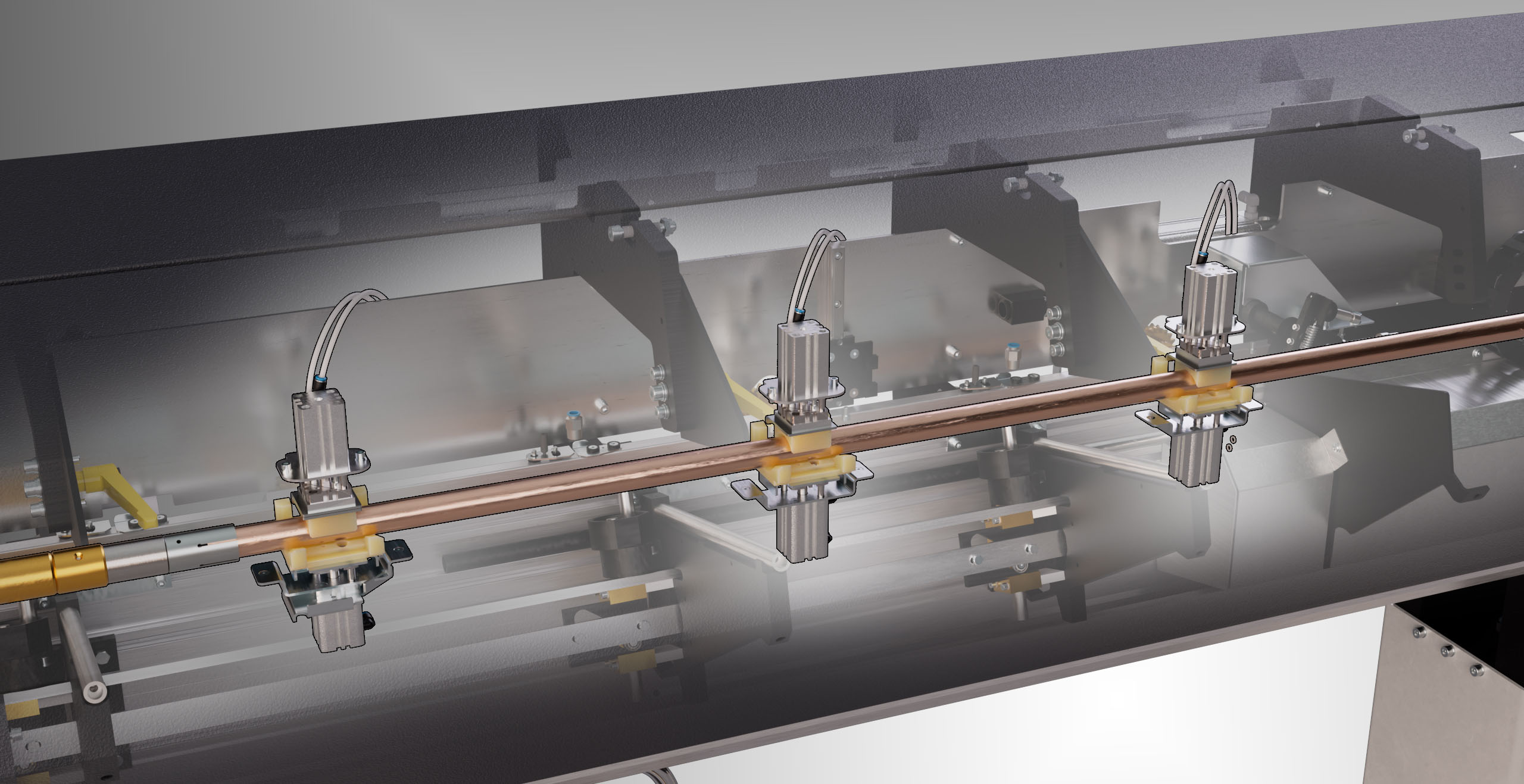

Think of an axle that is pre-cut and has end work completed on both sides, a very quick process. The advantage of slug loading is that, as the part is being processed, the next bar is staged in the v-tray of the bar feeder and queued to be loaded. This takes the loading time from around 30 seconds down to about five.

The operation is only performed on a short loader, because the short loader is programmed to push things into a spindle and stop when told to.

A slug load involves a single, solid material piece being machined into a specific shape or size. The rule for slug loading is: One bar equals one part. The operation is only performed on a short loader, because the short loader is programmed to push things into a spindle and stop when told to.

4 Applications for Slug Loading

1. Making the most out of your 12′ bar feeder’s remnants.

Depending on the remnant length from applications on a 12′ bar feeder, you can use slug loading to fashion additional parts.

2. Performing a second operation on an already-completed part

Let’s say you have a gear box that’s already been machined, and you need to perform a second operation on it — drilling a hole into one side of the gear box, a lightning fast operation. Simply set the completed gear box pieces on the Rebel 102 magazine and have them feed in. Rather than making the Rebel 102 perform bar changes for each bar, which can take up to 30 seconds (perhaps as long as the machining itself!), the short loader performs the operation, then has the next part push in its place, ready to go. The only time it takes is the time to push the bar from the v-tray to the spindle liner.

3. Working with material that’s already been cut to length

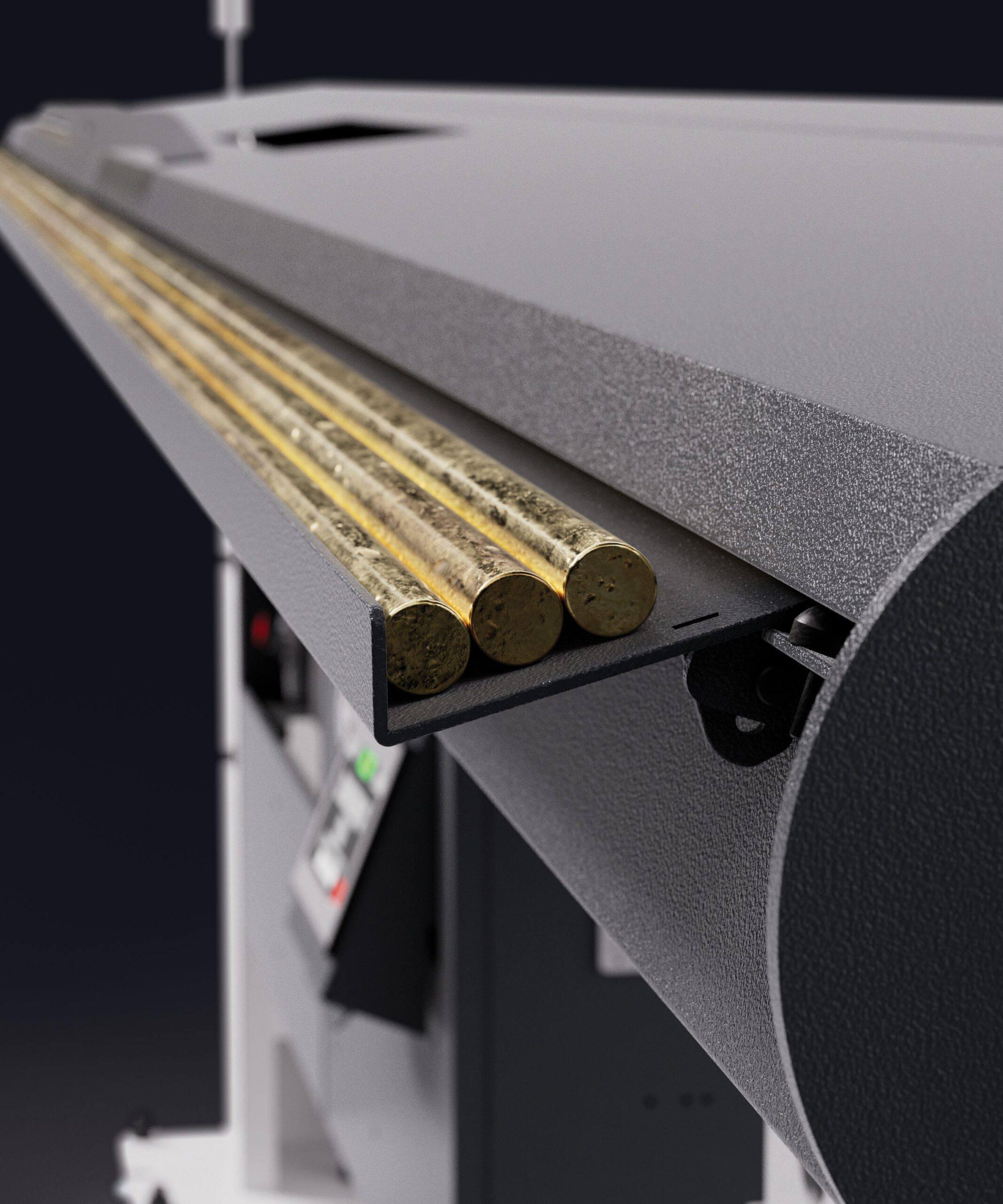

We’ve helped shops who worked with pressed brass that was not physically available as a 6’ bar. Rather, the customer would buy 8” pieces, and slug load each individual piece.

4. Working with challenging materials

Sometimes, an application demands you work with challenging, expensive, or hard-to-acquire materials, like stainless steel or titanium. This could include chromed material, or maybe a glass bar that’s already been polished. Slug loading is perfect in these applications, because only the necessary material is machined, so the technique produces less waste.

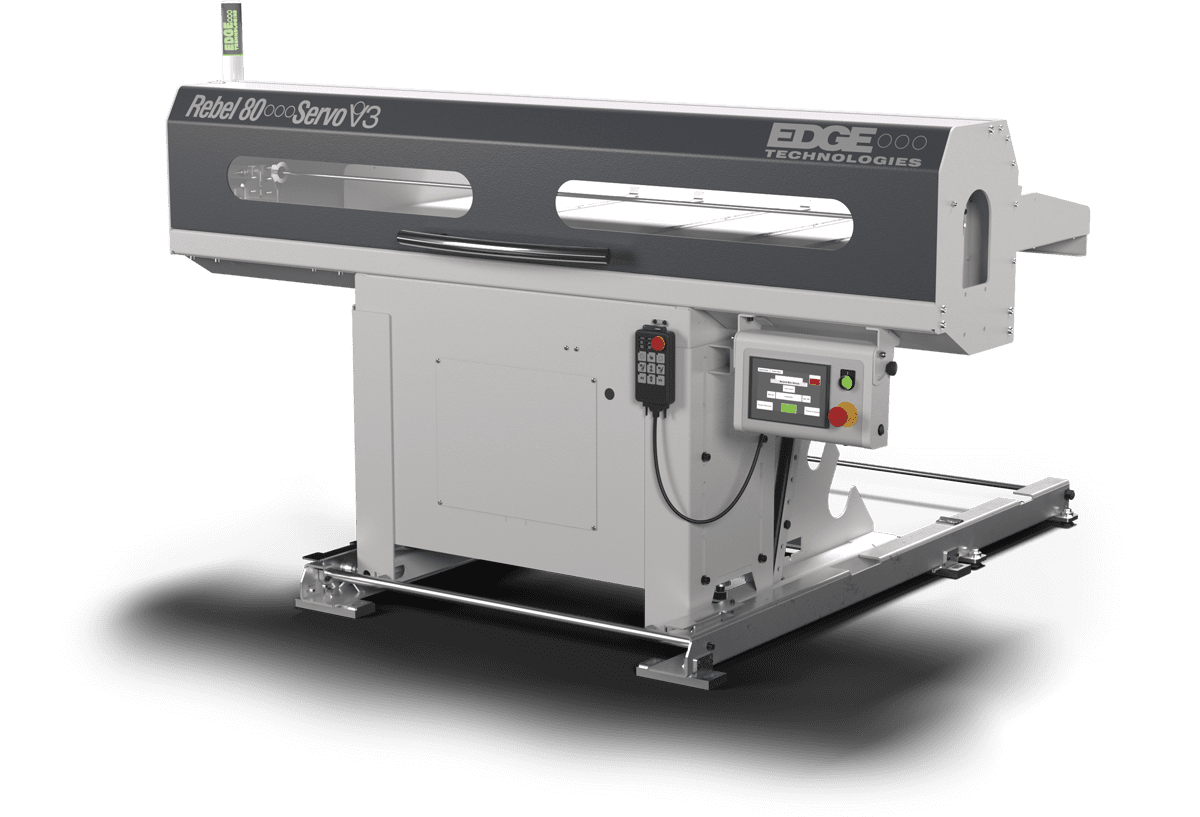

Is a short loader for you? Edge Technologies can guide you.

Slug loading is a useful technique that is available on our Rebel 80 Servo V3 and Rebel 102 short loaders. It is great, because you don’t have to deal with a remnant, and it produces less waste. Slug loading is one of the specialized part programs built into the HMI, enabling you to eliminate a whole stroke of the machine, so that the pre-feed pusher is the only thing that you use instead.

If you have any other questions, please do not hesitate to contact us. We are committed to giving you the tools and service you need so you can focus on high-quality products and exceptional service for your customers.