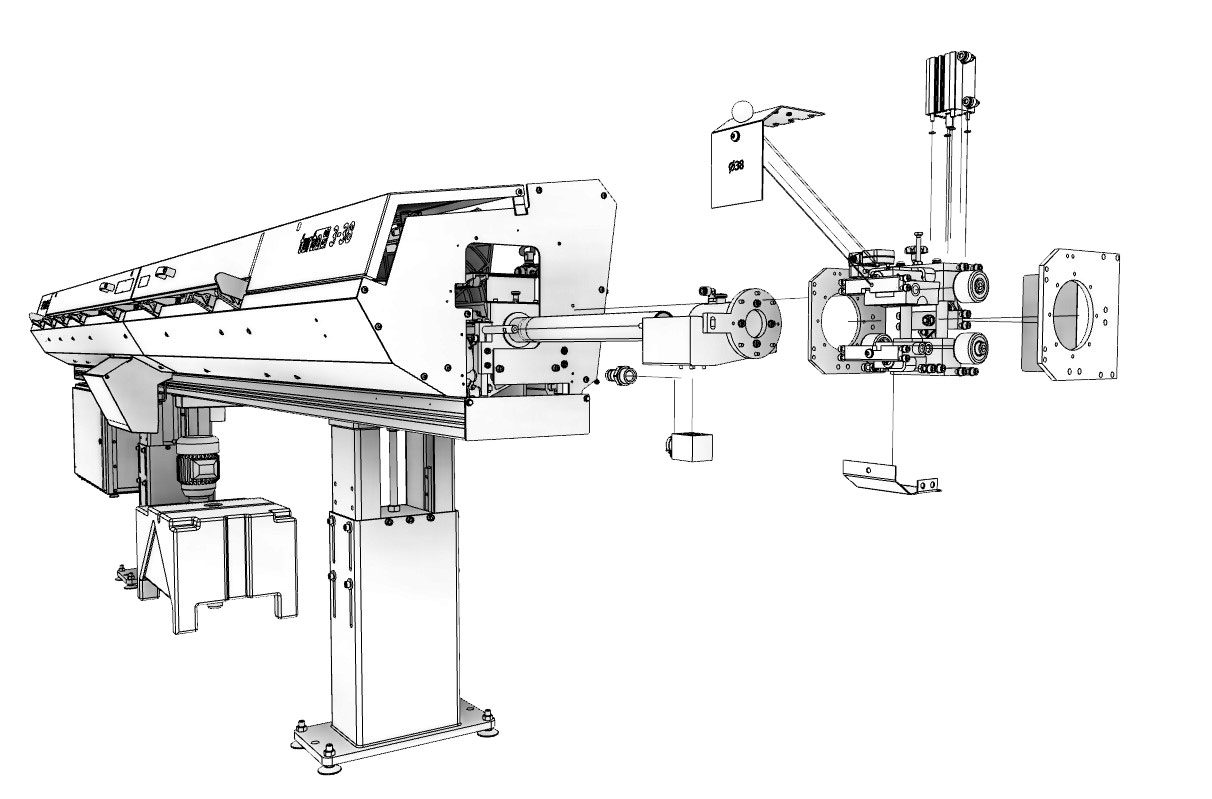

How Does the Bar Feeder Load Random Length Bar Stock?

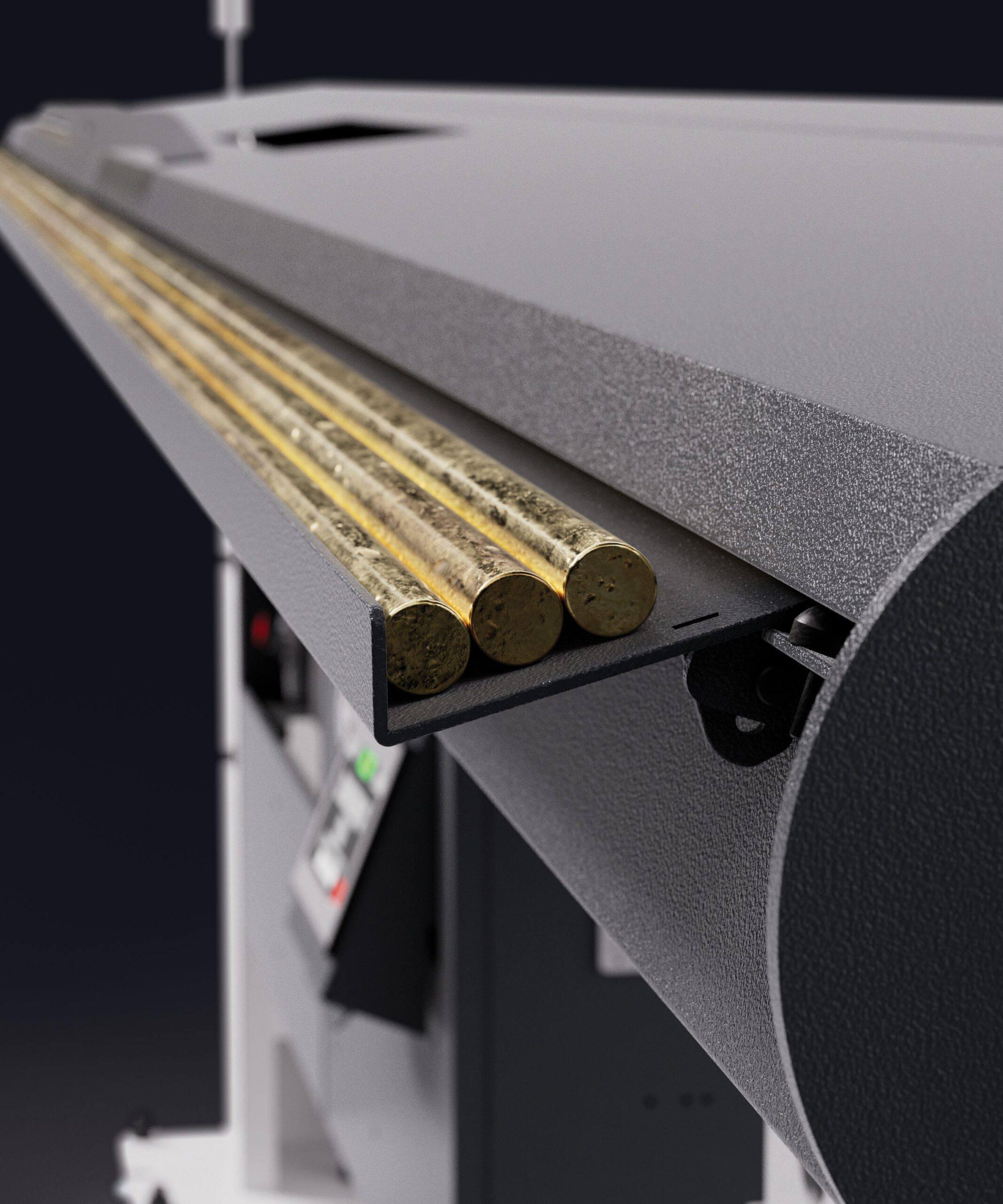

Imagine you got bar stock from your suppliers that came at random lengths. Or you have materials left over or didn’t use a full bar, and you want to use that in the future. Maybe you want to make the most of your remnants.

Edge Technologies’ bar feeders are built to handle random length bar stock.

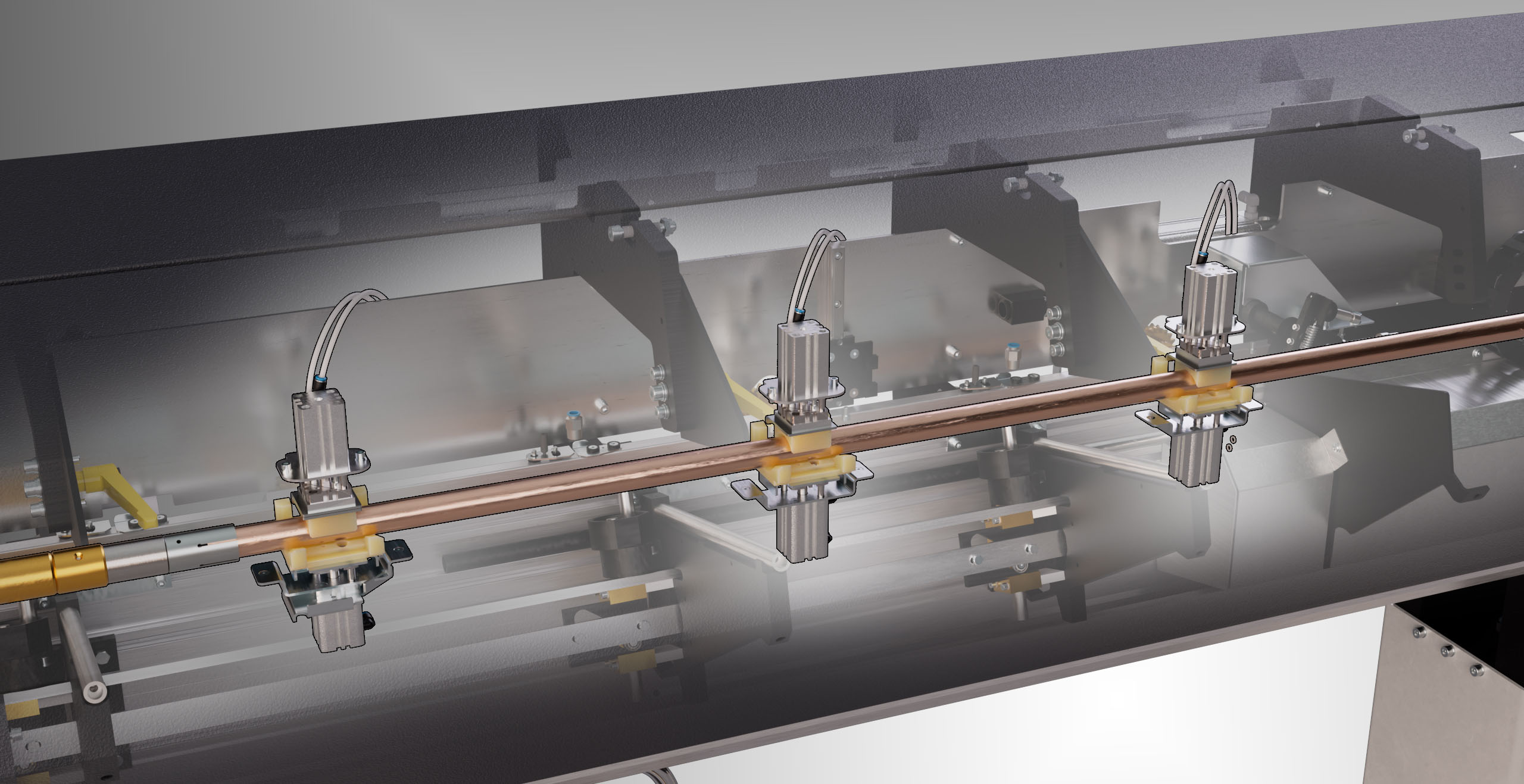

Our bar feeders use a pusher and measurement flag to determine each bar’s length. The pusher uses an encoder to know where its position is. It advances the bar until it trips the measurement flag. When it gets tripped, the pusher/encoder knows where it’s at for its end-of-bar signal and gives you an accurate measurement.

That gives us less scrap, higher material yield, and we can run lights out confidently.

Check out this video this see the measurement flag in action:

Edge Technologies’ bar feeders are built to handle random length bar stock. Our bar feeders use a pusher and measurement flag to determine each bar’s length. That gives us less scrap, higher material yield, and we can run lights out confidently.

For safety and proper feeding, the shortest bar you can run is 36 inches. Anything shorter risks falling into the remnant tray before it’s fully fed.

Every bar is held in the same spot of the guide channel set by the gripping fingers, giving all material the same starting position. The pusher presses the collet on at this position and advances the bar until the measurement flag is hit. The bar feeder calculates the position of front of bar and pusher for the O.A.L.

With Edge Technologies’ pusher/measurement flag system, you don’t have to cut everything to a single length. You can run bars of varying sizes with confidence, and keep lights-out runs safe, accurate, and productive.