Why RS Technology Is a Game Changer

A bar feeder should never limit the RPM of a CNC lathe. But, in recent years, on Swiss-type lathes, strokes have gotten longer. As a result, sheet metal gaps have widened, and shops have experienced what they call the Achilles Heel of bar feeders: a jump rope or tail whip effect where the unsupported area vibrates, causing tool chatter, surface finish issues, and reduced RPMs. Vibration issues are an industry-wide problem, not an Edge Technologies problem.

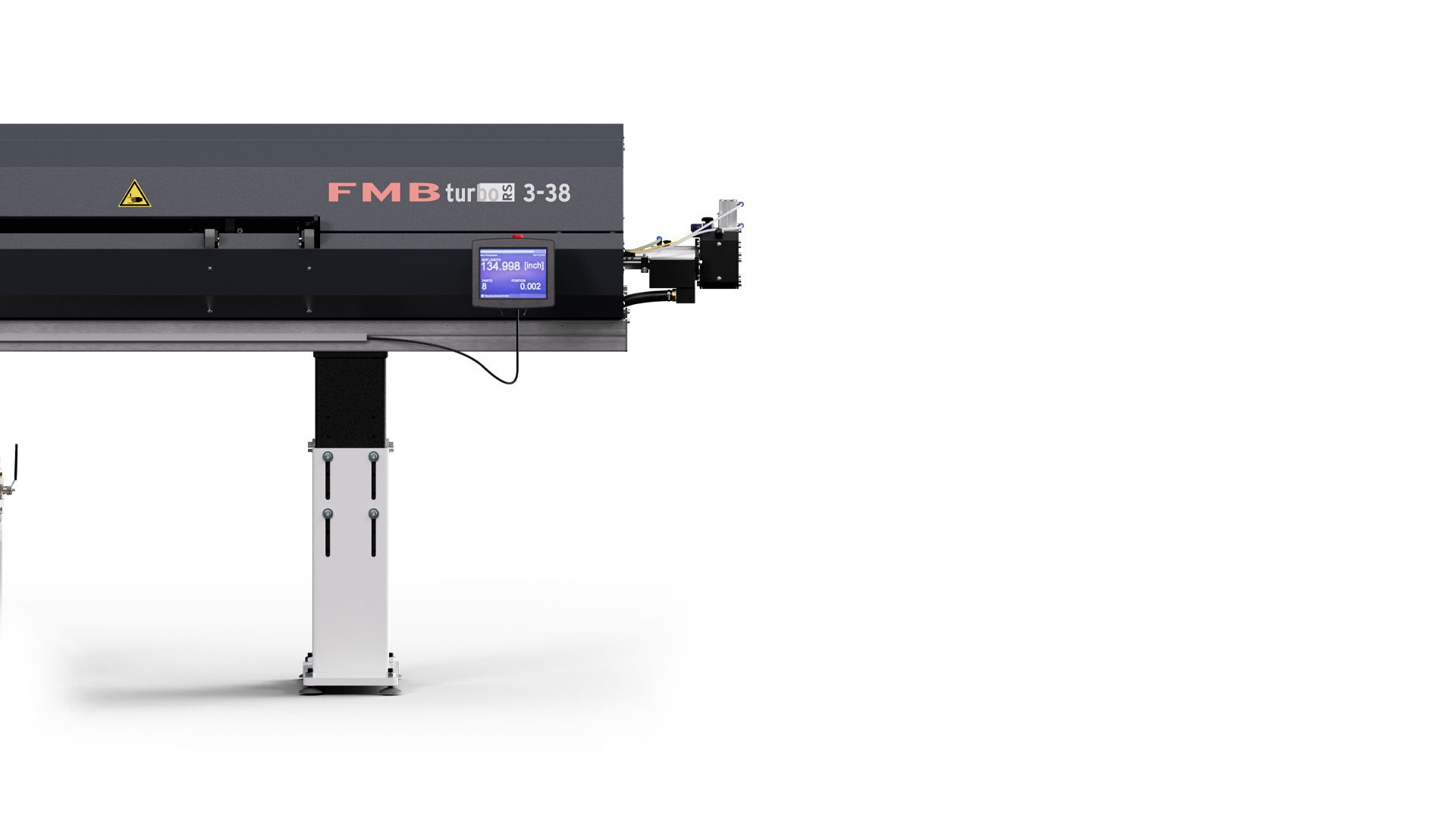

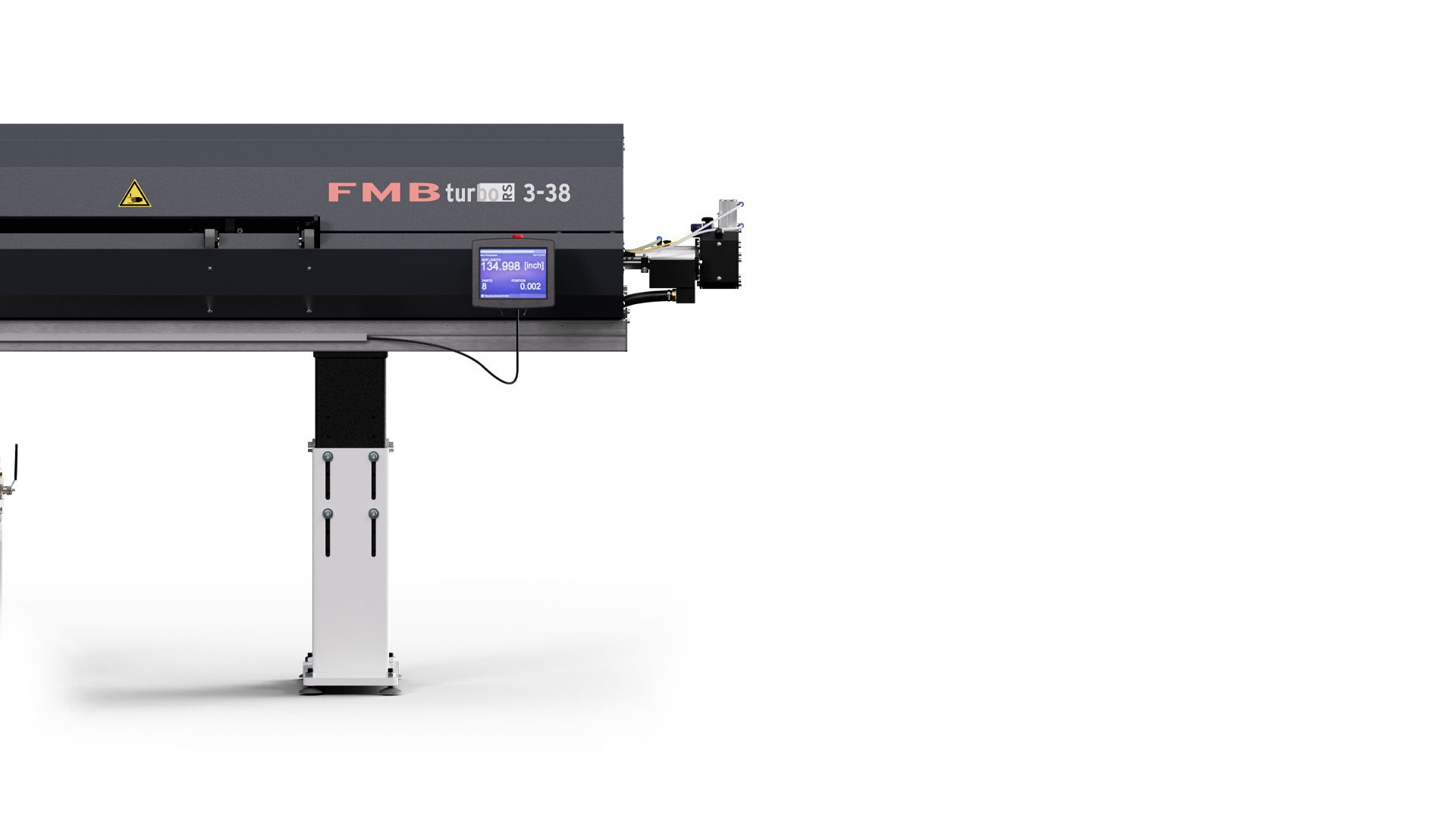

Revolutionary Sliding (RS) Technology addresses exactly that. The patented technology, rolling out through FMB, is the first revolutionary technical change to a bar feeder in probably 20 years, and is truly a game changer for sliding headstock lathes. Because it is patented, Edge Technologies is the only distributor in North America who can do this.

Let’s explore how RS Technology works, and 10 reasons it is a gamechanger.

How Does RS Technology Work?

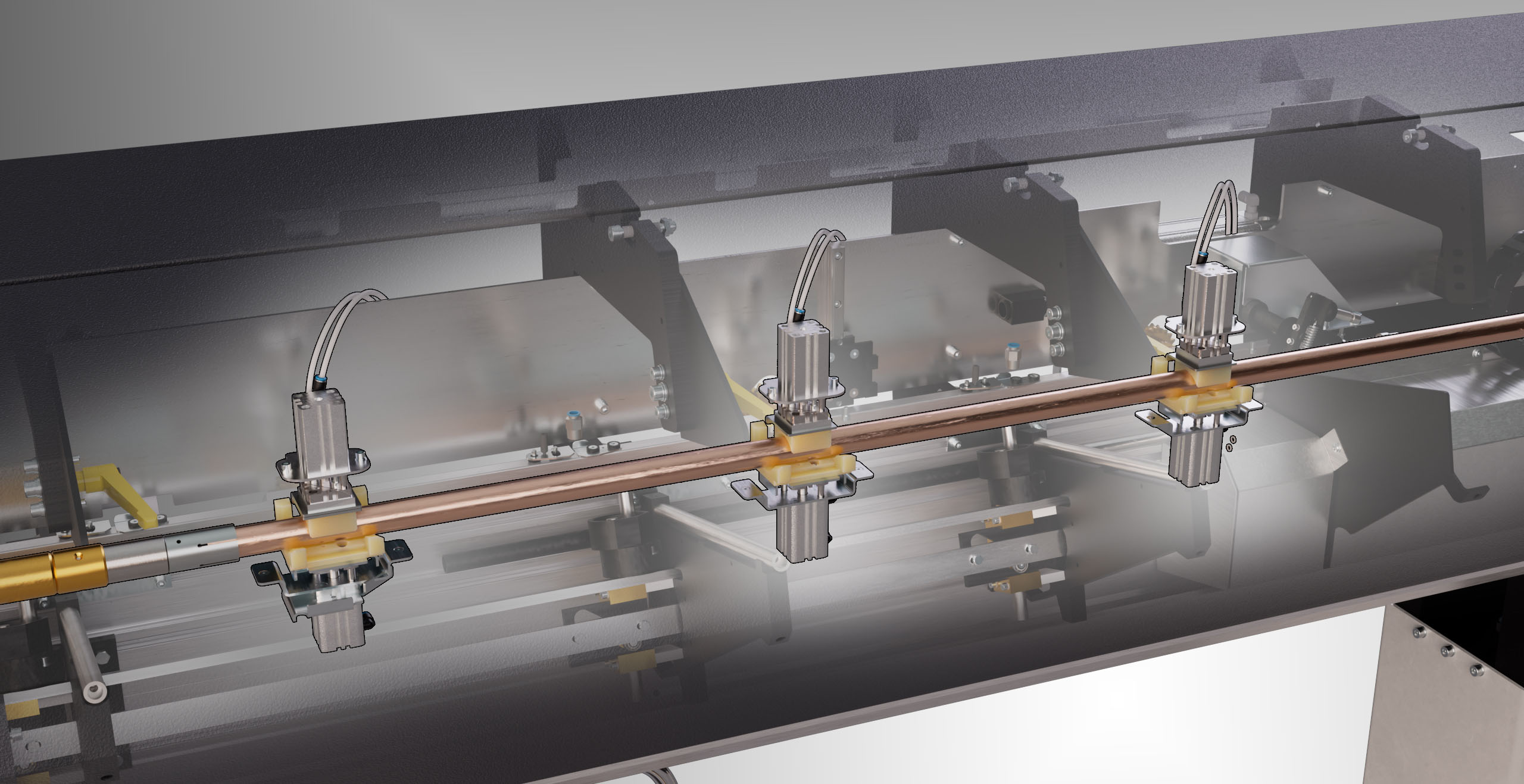

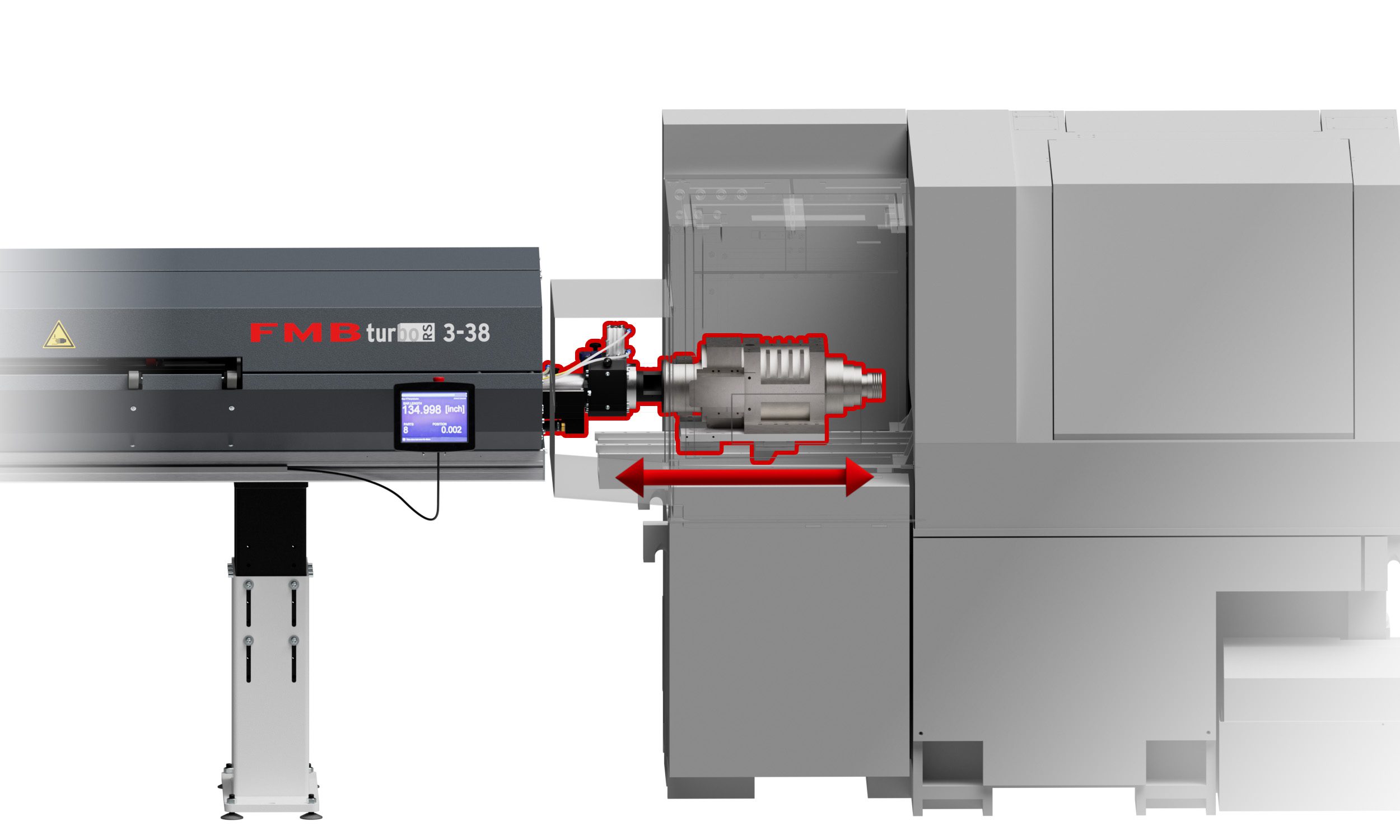

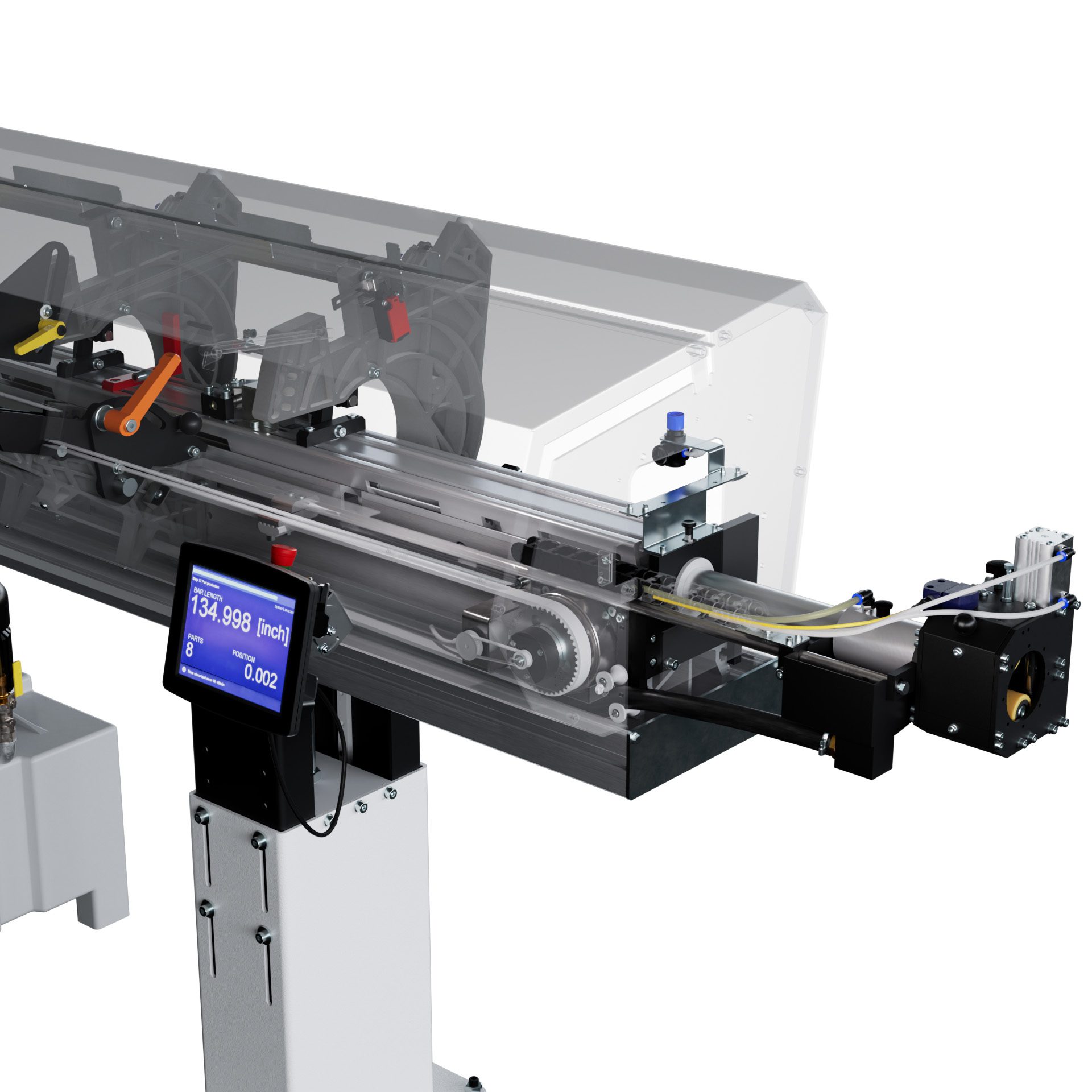

Instead of the telescopic nose device that traditionally connects the machine tool and bar feeder, the bar feeder uses RS technology. A steady-rest mounts directly to the back of machine tool’s headstock, providing material support at the back of the spindle, while an extension tube or guide module (what could be considered a sliding spindle liner) is internal to the bar feeder. As raw material travels, the integrated and oiled sliding guide module and moving steady rest provide superior bar pusher and stock support in the transition zone between the bar feeder and lathe spindle.

RS technology mounts a steady-rest directly to the back of machine tool’s headstock, providing material support at the back of the spindle, while an extension tube or guide module (what could be considered a sliding spindle liner) is internal to the bar feeder. As raw material travels, the integrated and oiled sliding guide module and moving steady rest provide superior bar pusher and stock support in the transition zone between the bar feeder and lathe spindle.

10 Reasons RS Technology Is a Game Changer

1. With the gap between bar feeder and lathe minimized, RS Technology reduces vibration and eliminates the jump rope effect.

Early performance indicators in Europe have shown 15% higher RPM, with some shops running ¾ bar stock at 10,000 RPM in non-guide-bushing mode.

2. RS Technology provides extra stability at the back of the spindle, where it is needed the most.

During one presentation, we saw an FMB Turbo RS 3-38 running 5/8 with no oil at 10,000 RPM, and the machine didn’t even vibrate enough to feel vibrations on the bar feeder hood.

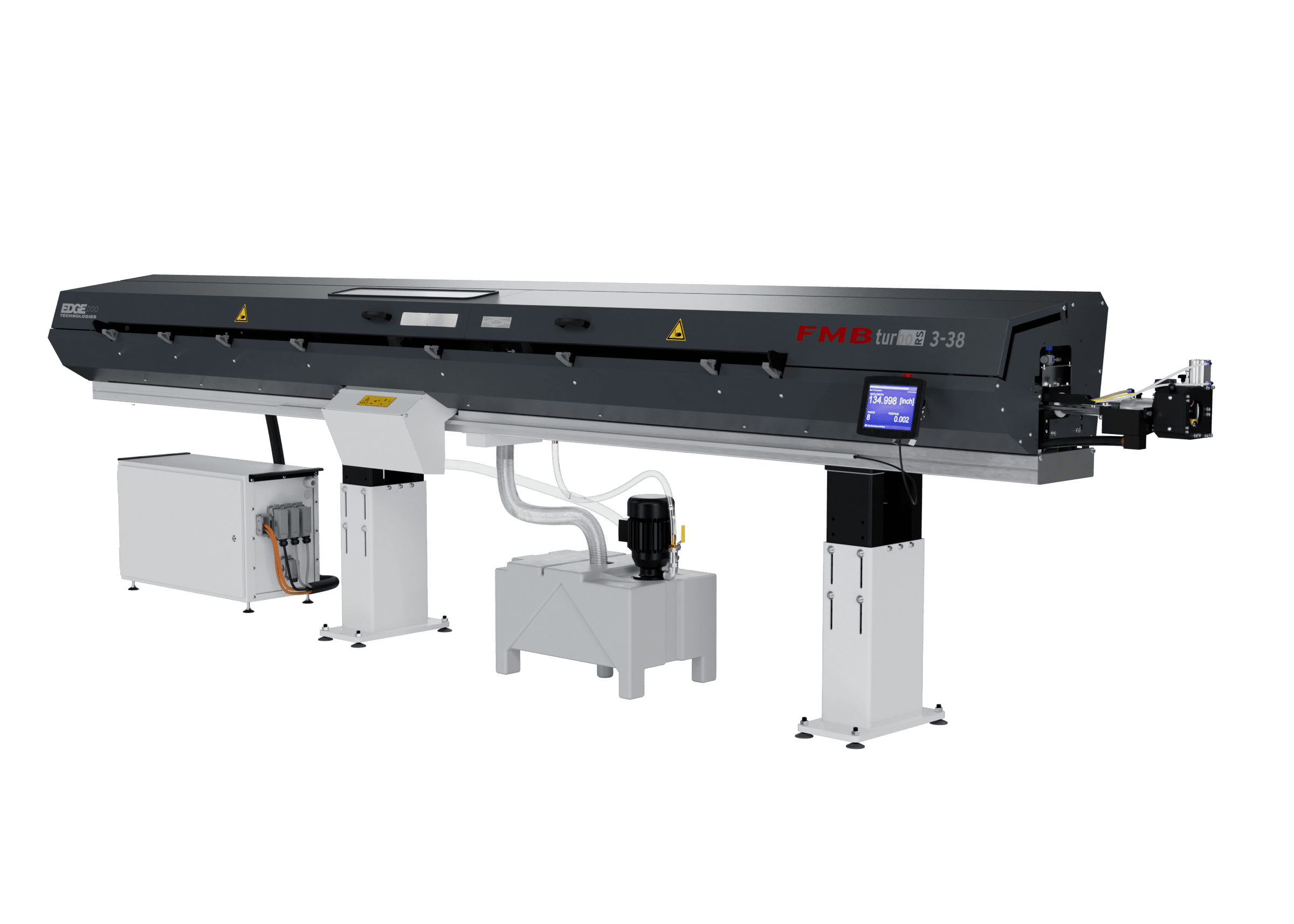

3. With the gap eliminated, RS Technology can be installed closer to the back of the machine tool, requiring less floor space.

On a shop floor, every bit of available space counts. And, ironically, while the RS is physically longer (about 8” to 10” longer), its overall footprint is smaller. The reason is that, without the telescopic nose, it saves about 12” to 18” in space.

In addition, on FMB’s Turbo RS 3-38 (the company’s flagship automatic magazine bar feeder, and first to roll out with RS Technology), a swing-out bar pusher bar system also reduces the total length of the loading magazine.

4. RS Technology spells bigger performance enhancements for bigger lathes while reducing the need for additional bar feeder accessories.

Bigger lathes especially require pusher extensions, axial shifts and MAVD’s. Because these are no longer needed, any increase in upfront cost is absorbed by what would be needed for accessories. In addition, it reasons that a fully extended telescopic nose causes the greatest jump rope effect. So, not only is the cost about the same, the performance is increased, as the traveling spindle liner eliminates the risk of jump rope effect.

5. RS Technology is especially useful for Swiss lathes with longer Z-axis strokes.

FMB’s RS technology eliminates the need for telescopic noses, extended pushers, and Z-axis axial track, all of which were accessories designed to minimize the gap between the bar feeder and lathe.

6. RS Technology simplifies the process for the end user.

With changeovers, you no longer need to take the steady rest off. Changeovers are as simple as pulling a pin for a guide channel and changing a tube to match the pusher.

7. RS Technology makes up the difference for any spindle weaknesses on a lathe.

Early performance indicators suggest 20% increase in tool life, especially on applications with big cuts, where the heat can be detrimental to the tool.

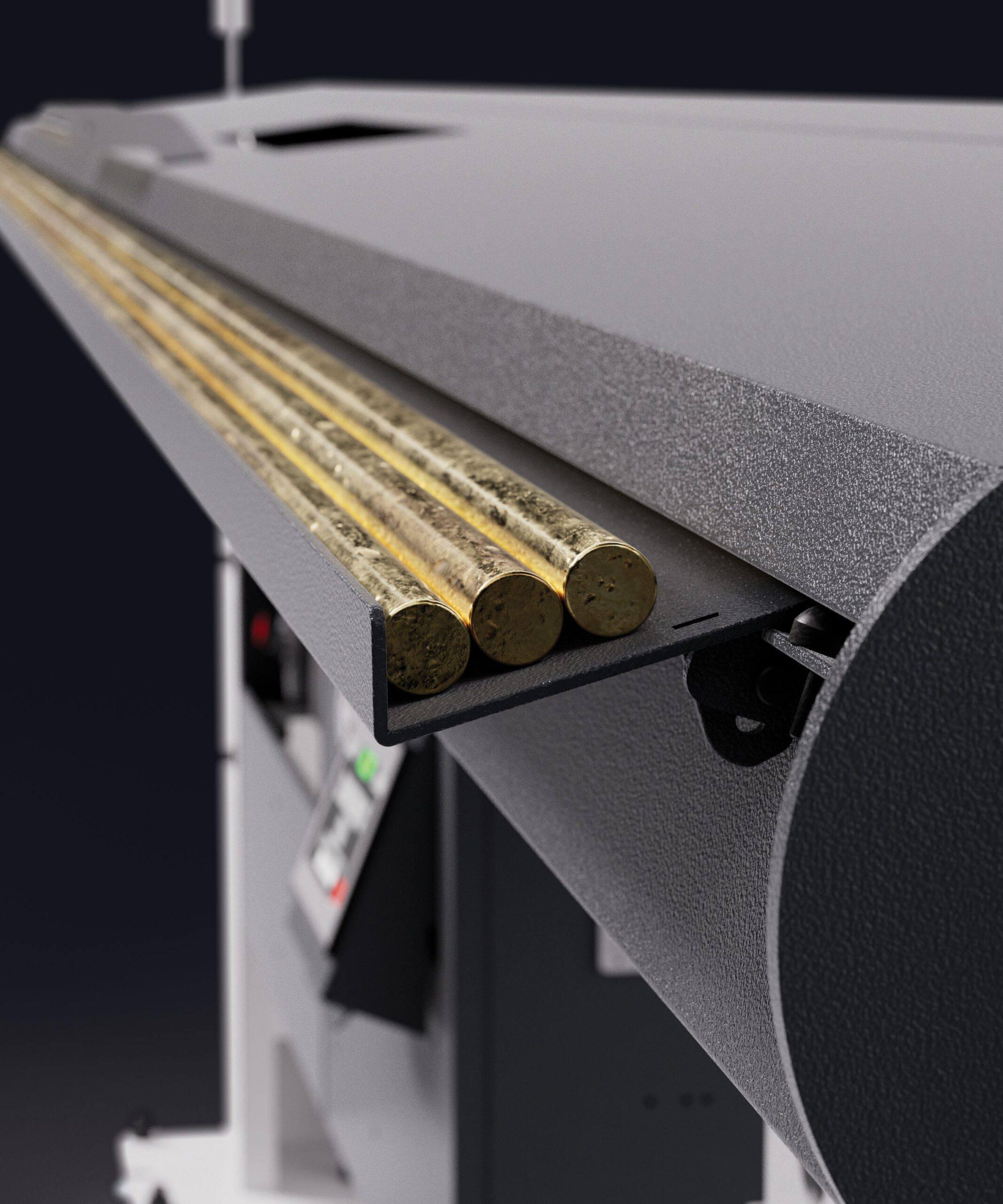

8. RS Technology works especially well for difficult materials, as well as profiled materials like hex stock.

Bent bar has been known to slip out of a pusher collet. What’s worse, if the pusher plane, AVD, and MAVD aren’t laser-lined on the same center, the pusher plane itself can cause the bar to arch. The RS outperforms all other machines with a wavy bar.

Whether because of price, availability or delivery, shops will purchase whatever material they can get. With the RS series, machinists now have more control, enabling them to maximize the RPM in the lathe, make better parts, have better surface finishes, and produce better quality even with inferior material straightness.

9. RS Technology is especially useful for demanding applications such as non-guide bushing mode.

The design eliminates the need for an axial shift device or pusher extension to make the bar feeder “longer” for non-guide-bushing/chucker applications. In addition, for those who need a 42mm guide channel set, the FMB Turbo RS 4-45 enables you to run 1 1/2 and 1 5/8 in a Swiss machine.

10. The RS is built on the same tried-and-true platform of the original Turbo 3-38.

The Turbo 3-38 has always led the way in bar feeding rigidity, and the RS will only increase the ability of the 3-38 line.

Edge Technologies can guide you with RS Technology.

The FMB Turbo series is already recognized for its ultra rigid extruded base and advanced performance characteristics. Adding RS Technology has taken the model to a whole new level of performance.

The technology is currently available on the FMB Turbo RS 2-20, FMB Turbo RS 3-38 and FMB Turbo RS 4-45, revolutionizing Swiss-type lathes across a wide spectrum of bar stock sizes. If you have any other questions, please do not hesitate to contact us. We are committed to giving you the tools and service you need so you can focus on high-quality products and exceptional service for your customers.