Everything You Need to Know about Automatic Magazine Bar Feeder Compatibility and Integration

Deciding on an automatic magazine bar feeder?

An automatic bar feeder can be a relatively low investment for enormous potential. A bar-fed lathe can run unattended for hours, even an entire shift, enabling lights-out machining that cuts costs and increases capacity.

Many factors go into deciding a bar feeder. Perhaps the two most important are compatibility and integration. And, to help you make the right decision, we’re going to share everything we know about bar feeder compatibility and integration.

An automatic bar feeder can be a relatively low investment for enormous potential. A bar-fed lathe can run unattended for hours, even an entire shift, enabling lights-out machining that cuts costs and increases capacity.

Why is bar feeder compatibility and integration so important?

Every automatic magazine bar feeder should do the following:

- Reduce time and effort in handling raw materials

- Support bar stock to minimize vibrations and improve surface finish

- Enable optimum spindle speeds for your machine tool

- Shorten changeover times

- Decrease material waste

- Deliver consistent, reliable performance

However, your specific machining needs mean that you need a specific bar feeder that fits your applications precisely. Some of those specifics include:

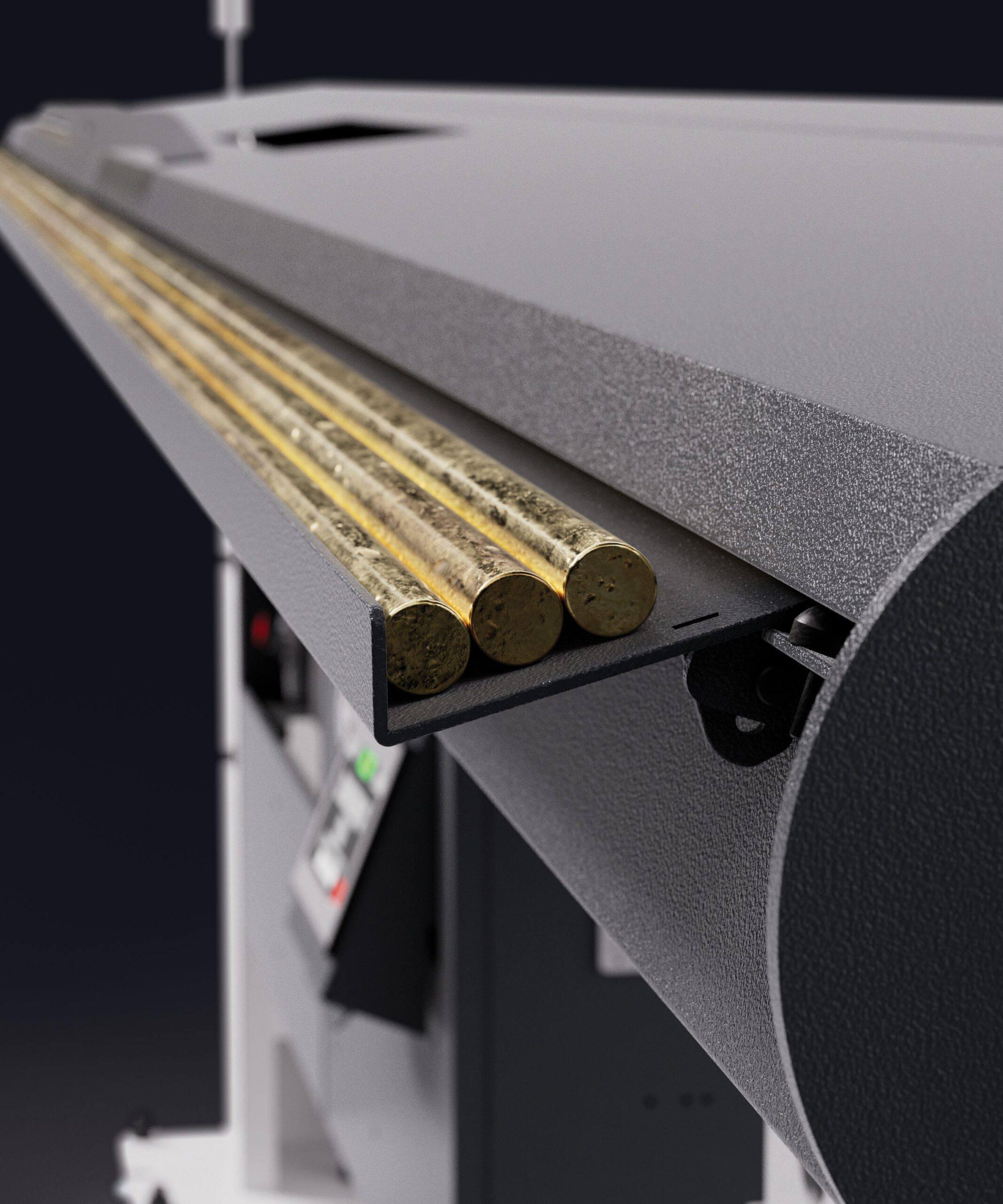

- Range of bar stock diameters

- Range of bar stock shapes, whether round, square or hexagonal

- Size of production runs

- Part lengths

- Desire for unattended production

- Amount of available floor space

These specifics are at the heart of compatibility and integration.

What is compatibility?

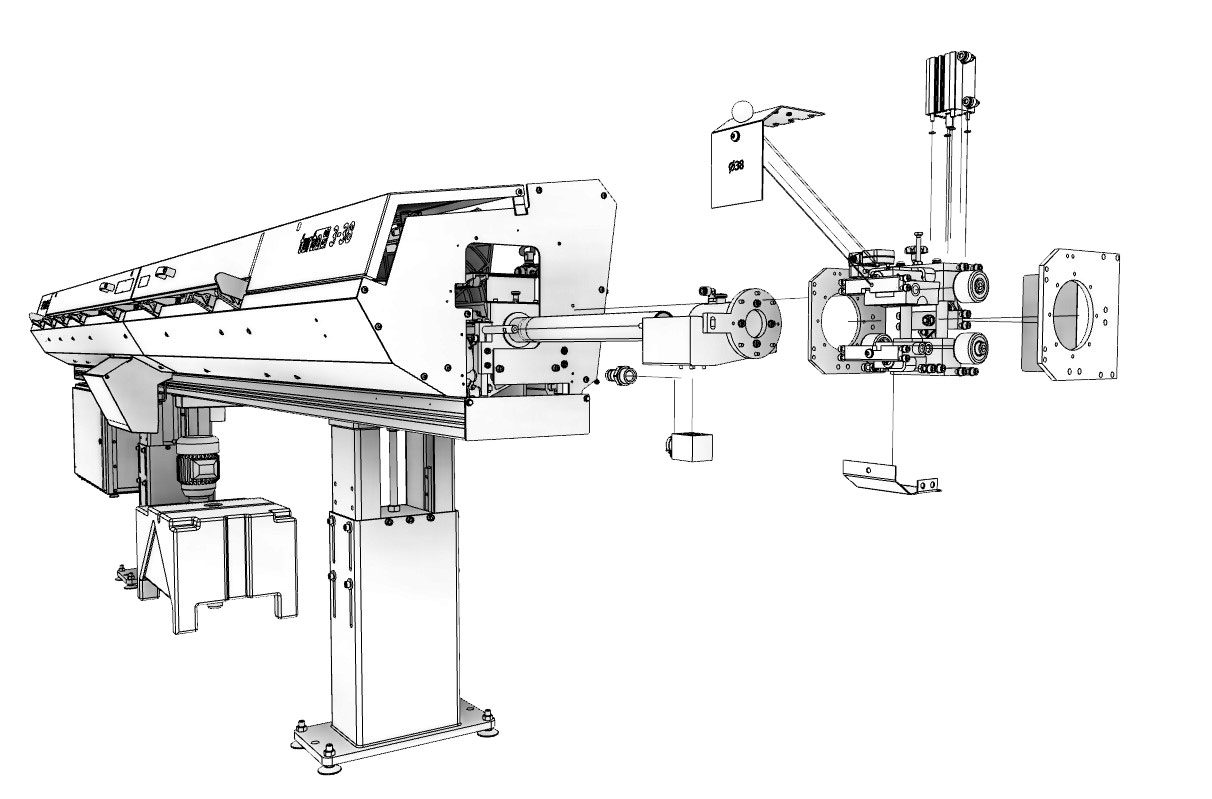

Compatibility refers to whether the bar feeder is well-suited to your CNC lathe. For example, if your application is designed for short-run productions that require regular changeover, a short loader might be better.

Generally speaking, your main choices are:

- 12’ bar feeders

- 6’ bar loaders

- Short loaders for spindle-length bars

(We offer 24’ options as well.)

But there are hundreds of ways to configure a bar feeder beyond those main choices.

What is integration?

Integration focuses on smoothly incorporating the bar feeder into your manufacturing environment. Do the controls between bar feeder and lathe speak to each other? Successful integration is a collaborative effort that involves coordination between your team and the provider.

1. Material Compatibility

The automatic bar feeder should be compatible with the types of materials you plan to process. We offer a two-tier lineup of magazine bar feeders, and most of our bar feeders are designed for feeding round, square and hexagonal bar material. We also can feed asymmetrical shapes, profiled stocks and elaborate extrusions.

For finer and more delicate materials, we have specifically designed bar feeders, particularly the Micromag 20 and the Minimag 20, with a single pusher. This helps reduce the risk of damage to the bar.

We also provide accessories, like a walking beam in the Micromag 20 and scroll-style loading (also known as worm gears) in the Ranger 112, which look like stair steps that walk the bar down one by one, rather than letting gravity do the work and risking multiple bars bunching and loading.

These features and accessories ensure that the bar feeder is compatible with your specific material needs.

2. Space and Layout Compatibility

Ensure that your facility has adequate space. We can provide drawings to ensure the automatic bar feeder will fit in your shop.

Evaluate your facility’s available space, including the bar feeder’s footprint and safety clearances. If floorspace is limited, you might consider our FMB turbo 2-20, which is intentionally designed to maximize floor space.

Also consider the layout of your production line to determine the optimal placement of the magazine bar feeder for efficient material flow. Please note: Your unit will either feed left to right or right to left. We have products that can accommodate either.

3. Control System Compatibility

All of our machines are designed to universally adapt to every lathe, so that the control system of the bar feeder is compatible with your CNC lathe’s control system.

4. Programming Compatibility

Verify that the programming language and software used for the automatic bar feeder are compatible with your CNC lathe’s programming capabilities. We work with each of our partners to ensure this is the case.

5. Workholding Compatibility

When you purchase an automatic magazine bar feeder from us, we provide guide bushing and lathe and bar feeder collets.

We recommend you invest in ultra-precision collets. Although they cost more money upfront, they ultimately let you take more control of your process and save you tooling or parts complications down the line. We offer a complete line of high-quality parts.

6. Customization and Flexibility

In cases when a solution goes beyond our standard product, we can adapt to specific manufacturing requirements.

7. Maintenance and Service Compatibility

Our responsibility is to ensure that replacement parts and service support are readily available, including for legacy parts. We respond immediately – within 24 hours with a plan of action, and typically we send a field service technician out in a matter of weeks. There’s no telling the length we’ll go to ensure satisfaction. We have even cannibalized a bar feeder to get a client a part they needed.

8. Future Scalability

Assess whether the magazine bar feeder can scale with your production needs, including accessories like pusher extensions. Compatibility with future upgrades or expansions is crucial for long-term efficiency.

9. User Training and Operator Compatibility

Ensure that your operators can be trained to use the automatic bar feeder effectively and that it is user-friendly and compatible with your team’s skills and expertise.

1. Physical Installation

Proper installation is critical. That’s why we’re proud to have the largest service team in the automatic magazine bar feeder industry, with over 40 field service technicians and an average tenure of 7.7 years. There’s not much we haven’t seen and not much we can’t overcome. Plus, our regional service approach empowers us to stay in tune with what you need and enables us to respond quickly.

2. Control System Integration

The control system of the magazine bar feeder must seamlessly integrate with your CNC lathe’s. This involves setting up communication protocols and ensuring that the two systems work together harmoniously. On our Edge lineup of bar feeders, we write the software ourselves, giving us the control to ensure a smooth integration.

3. Programming and Setup

Program the automatic bar feeder to work in coordination with your CNC lathe. This includes configuring the feeder to load and to feed materials at the right times and in the correct quantities. Our touchscreen HMI comes with 300-part storage.

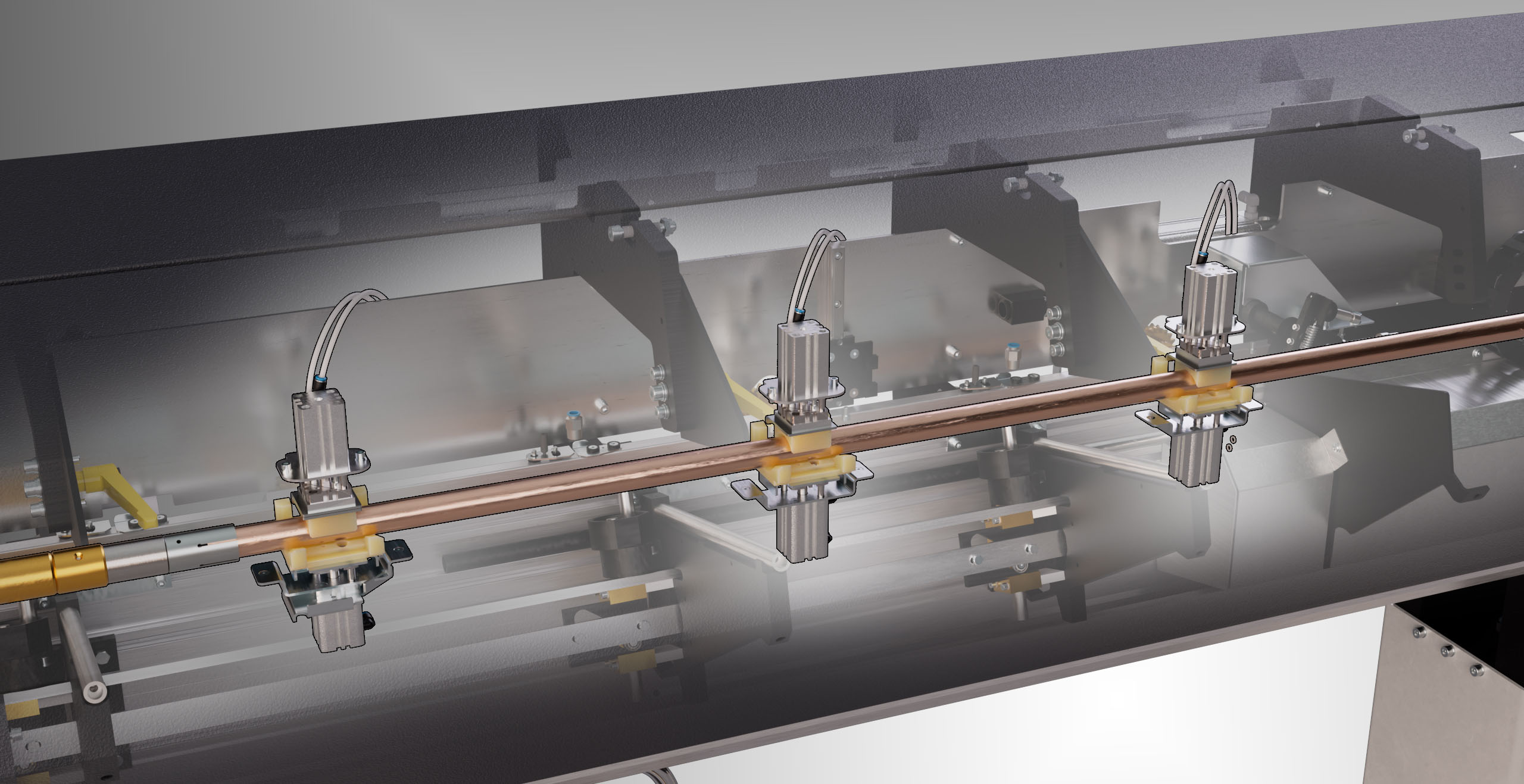

4. Material Handling Setup

Adjust the magazine bar feeder to handle your specific types of materials. Almost all our machines come with quick change channel sets, which can be a real cost-saver, especially for lots of changeovers. We even have auto adjust features on our FMB turbo 5-65, FMB turbo 8-80, and FMB turbo 20-100, where you can command the change in the HMI and then only have to change the collet.

Check out what one of our clients has to say about our quick change channel sets: https://youtu.be/awh2MCrFxCs?t=86

5. Testing and Calibration

Thoroughly test the integrated system to ensure it operates smoothly. Calibrate the automatic bar feeder for precise material handling and positioning. Our field technicians work with you to conduct trial runs with actual materials to validate the integration.

6. Operator Training

We train your operators to use the integrated magazine bar feeder efficiently and safely. We ensure they understand the operation, programming, and maintenance procedures, and help you create clear operating instructions and safety protocols.

We also offer free phone support for life to the original owner for as long as they own the equipment.

7. Maintenance and Service Integration

Establish a maintenance schedule for the integrated system, including a plan for simple parts like collets, rotating tips and pusher flags that wear out frequently. The nice thing about working with us is that we guarantee “cradle-to-grave” technical support and service. We pride ourselves on treating customers who are 20 years old the same as we treat customers who are two weeks old.

8. Operator Feedback and Improvement

Encourage operators to provide feedback for continuous improvement and refinement.

1. Material Compatibility

The automatic bar feeder should be compatible with the types of materials you plan to process. We offer a two-tier lineup of magazine bar feeders, and most of our bar feeders are designed for feeding round, square and hexagonal bar material. We also can feed asymmetrical shapes, profiled stocks and elaborate extrusions.

For finer and more delicate materials, we have specifically designed bar feeders, particularly the Micromag 20 and the Minimag 20, with a single pusher. This helps reduce the risk of damage to the bar.

We also provide accessories, like a walking beam in the Micromag 20 and scroll-style loading (also known as worm gears) in the Ranger 112, which look like stair steps that walk the bar down one by one, rather than letting gravity do the work and risking multiple bars bunching and loading.

These features and accessories ensure that the bar feeder is compatible with your specific material needs.

2. Space and Layout Compatibility

Ensure that your facility has adequate space. We can provide drawings to ensure the automatic bar feeder will fit in your shop.

Account for the feeder’s footprint, loading area and any required safety clearances. For example, if space is a premium, you might consider our FMB turbo 2-20, which is intentionally designed to maximize floor space.

Also consider the layout of your production line to determine the optimal placement of the magazine bar feeder for efficient material flow. Our standard loading configuration is left to right, but we also have units that feed right to left.

3. Control System Compatibility

All of our machines are designed to universally adapt to every lathe, so that the control system of the bar feeder is compatible with your CNC lathe’s control system.

4. Programming Compatibility

Verify that the programming language and software used for the automatic bar feeder are compatible with your CNC lathe’s programming capabilities. We work with each of our partners to ensure this is the case.

5. Workholding Compatibility

When you purchase an automatic magazine bar feeder from us, we provide guide bushing and lathe and bar feeder collets. We offer a complete line of high-quality parts, meaning compatibility should not be an issue.

6. Customization and Flexibility

In cases when a solution goes beyond our standard product, we can adapt to specific manufacturing requirements.

7. Maintenance and Service Compatibility

Our responsibility is to ensure that replacement parts and service support are readily available, including for legacy parts. We respond immediately – within 24 hours with a plan of action, and typically we send a field service technician out in a matter of weeks. There’s no telling the length we’ll go to ensure satisfaction. We have even cannibalized a bar feeder to get a client a part they needed.

8. Future Scalability

Assess whether the magazine bar feeder can scale with your production needs, including accessories like pusher extensions. Compatibility with future upgrades or expansions is crucial for long-term efficiency.

9. User Training and Operator Compatibility

Ensure that your operators can be trained to use the automatic bar feeder effectively and that it is user-friendly and compatible with your team’s skills and expertise.

1. Physical Installation

Proper installation is critical. That’s why we’re proud to have the largest service team in the automatic magazine bar feeder industry, with over 40 field service technicians. There’s not much we haven’t seen and not much we can’t overcome. Plus, our regional service approach empowers us to stay in tune with what you need and enables us to respond quickly.

2. Control System Integration

The control system of the magazine bar feeder must seamlessly integrate with your CNC lathe’s. This involves setting up communication protocols and ensuring that the two systems work together harmoniously. On our Edge lineup of bar feeders, we write the software ourselves, giving us the control to ensure a smooth integration.

3. Programming and Setup

Program the automatic bar feeder to work in coordination with your CNC lathe. This includes configuring the feeder to load and to feed materials at the right times and in the correct quantities. Our touchscreen HMI comes with 300-part storage.

4. Material Handling Setup

Adjust the magazine bar feeder to handle the specific types of materials you’ll be processing. Almost all our machines come with quick change channel sets, which can be a real cost-saver, especially for lots of changeovers. We even have auto adjust features on our FMB turbo 5-65 and FMB turbo 8-80, where you can command the change in the HMI and then only have to change the collet.

Check out what one of our clients has to say about our quick change channel sets: https://youtu.be/awh2MCrFxCs?t=86

5. Testing and Calibration

Thoroughly test the integrated system to ensure it operates smoothly. Calibrate the automatic bar feeder to achieve precise material handling and positioning. Our field technicians work with you to conduct trial runs with actual materials to validate the integration.

6. Operator Training

We train your operators to use the integrated magazine bar feeder efficiently and safely. We ensure they understand the operation, programming, and maintenance procedures, and help you create clear operating instructions and safety protocols.

7. Maintenance and Service Integration

Establish a maintenance schedule for the integrated system, including a plan for simple parts like collets, rotating tips and pusher flags that wear out frequently. The nice thing about working with us is that we guarantee “cradle-to-grave” technical support and service. We pride ourselves on treating customers who are 20 years old the same as we treat customers who are two weeks old.

8. Operator Feedback and Improvement

Encourage operators to provide feedback on the integrated system’s performance and usability. Use this feedback for continuous improvement and refinement.

And here are some frequently asked questions about compatibility and integration:

Closed Automatic Magazine Bar Feeder Question

1. How do I calculate space and layout requirements for integrating an automatic magazine bar feeder?

Space and layout planning matters. When we install a bar feeder, we use a laser-guided system to ensure it is completely level. A crooked bar feeder will not produce quality materials.

Proper planning not only maximizes the benefits of your bar feeder but also enhances safety and workflow optimization:

Efficient Material Flow. Optimizing the layout ensures that materials move smoothly from the bar feeder to your CNC lathe, minimizing the risk of congestion or material handling bottlenecks.

Operator Safety. Proper spacing and layout help create a safe working environment for your operators, reducing the risk of accidents and injuries.

Access for Maintenance. Adequate space allows technicians to access and maintain the bar feeder without disrupting production.

Future Scalability. Planning for potential growth or changes in your manufacturing operation ensures that your layout can accommodate future needs.

Here’s a checklist to calculate space and layout requirements:

1. Create a Detailed Floor Plan

Using the measurements and considerations above, create a detailed floor plan.

2. Assess CNC Lathe Placement

If you buy a lathe and magazine bar feeder together, identify the location of your CNC lathe. Ensure that it is positioned in a way that allows the bar feeder to feed materials directly into the machine without an obstruction like an I-beam.

3. Measure the Bar Feeder Dimensions

We make this easy for you, by providing CAD drawings that show the dimensions of the bar feeder itself, including its length, width, and height.

4. Consider Operator Accessibility

Determine where operators will need to stand to load materials, monitor operations, and access controls. Ensure that there is enough space for operators to work comfortably and safely.

5. Calculate Material Loading and Unloading Zones

Consider where the bar stock will be loaded into the feeder and where machined components will be unloaded. Ensure that these zones are easily accessible and that there is sufficient space for materials to move.

6. Account for Safety Clearances

Factor in any safety clearances required by regulations and manufacturer recommendations. This includes clear pathways for operators, emergency stops, and safety barriers if necessary.

7. Review and Refine

Review your floor plan with your team and make any necessary refinements to ensure that it aligns with your production needs and safety requirements.

2. What are the best practices for maximizing efficiency?

The real benefits of a bar feeder come when you optimize its integration into your workflow. Here are some tips to get the most out of your bar feeder:

1. Regular Maintenance is Key

Maintain a regular maintenance schedule for your bar feeder. This includes cleaning, lubricating, and inspecting critical components. Well-maintained equipment runs more reliably and with fewer hiccups, reducing downtime.

2. Operator Training and Skill Development

Invest in training for your operators on the automatic magazine bar feeder. They should be well-versed in loading materials, programming, and troubleshooting common issues. Skilled operators can make quick adjustments, reducing interruptions in production.

3. Material Preparation

Properly prepare your materials for material straightness. The straighter the bar, the easier it is to feed. Ensure each bar is cut to the right length, has clean ends, and is free from defects. Quality material preparation minimizes jams and ensures a smoother process. For more on this, including a helpful checklist and video, click here.

4. Optimize Programming

Have your lathe applications engineer tailor your CNC lathe’s program to take full advantage of the bar feeder’s capabilities. We can help you optimize for minimal bar remnants and times, and provide best practices to reduce tool wear.

5. Keep an Eye on Workholding

Regularly inspect and replace workholding components, such as collets and guide bushings, as needed. Worn or damaged tooling can lead to downtime.

6. Implement Predictive Maintenance

Consider implementing predictive maintenance techniques. Utilize sensors and monitoring systems to track the health of your bar feeder, and identify potential issues before they cause breakdowns. We have a saying around the shop: “The least of your problems is our bar feeder.” Predictive maintenance makes sure that’s true.

3. What should I expect from the installation process?

The installation process is a crucial step that should not be taken lightly. Our team brings a wealth of expertise and experience to the table. They understand not just the intricacies of the automatic magazine bar feeder but the intricacies of the CNC lathe as well, since the two need to be one with each other.

Let’s consider three components: pre-installation, installation, and post-installation.

Pre-Installation

Before we even sell you an automatic magazine bar feeder, our team helps design an efficient workflow that accounts for factors such as bar stock size, tool changes, and part ejection, ensuring that your lathe and bar feeder work harmoniously.

Then, because each machining operation is unique, and your bar feeder integration will likely require some degree of customization, our team helps tailor the integration to suit your production needs, whether it involves special tooling, adapters, or software configurations.

Installation

Our field service technicians plan and execute the integration efficiently, minimizing downtime and disruptions to your production schedule during the transition period. Their experience enables them to complete the installation quickly and accurately, allowing you to get your lathe with the new bar feeder up and running as soon as possible.

The precise alignment of a bar feeder to your lathe is critical for its proper functioning. Our field service technicians have the knowledge and tools to ensure that the bar feeder is aligned to perfection and adheres to manufacturer specifications. Compliance with these guidelines is essential to maintain warranty coverage and optimal equipment performance. Plus, proper alignment and installation reduce wear and tear on components, extending the lifespan of your equipment and minimizing the need for repairs.

In the event of unexpected challenges or issues during installation, our field service technicians have the knowledge and problem-solving skills to address them effectively. They can diagnose and resolve issues without causing further delays or complications.

Bar feeders and lathes are powerful machines that can be hazardous if not installed correctly, so our field service technicians are well-versed in safety protocols and take all necessary precautions to protect both the equipment and your workers during installation.

Our field service technicians then provide training to your operators, so that your team understands how to operate the integrated system effectively, troubleshoot common issues, and make the most of its features.

Post-Installation

Manufacturing technology evolves, and your integration should be designed with future needs in mind. We can guide you to future-proof your investment by considering scalability and adaptability to emerging technologies.

When we install your bar feeder, you gain peace of mind knowing that the installation has been carried out correctly. Our promise of “cradle-to-grave” tech support is our stamp that we believe in the quality of the install. You can confidently rely on the equipment for your production needs.

Edge Technologies can guide you with your automatic magazine bar feeder compatibility and integration considerations

That about sums it up, everything you could possibly want to know about bar feeder compatibility and integration.

If you have any other questions, please do not hesitate to contact us. Edge Technologies is the go-to choice for high-mix job shops running CNC lathes. As an industry leader with decades of experience, we have a deep understanding of the needs and challenges of modern manufacturing, and over 19,000 successful installations to prove it. Should you choose to work with us, we will take a consultative approach, as a trusted advisor, tailoring a bar feeder to your specific requirements and ensuring long-term technical support and service. We understand that no bar feeder can optimize the performance of your CNC lathe unless the two are completely compatible and properly integrated. That’s why we are committed to giving you the tools and service you need so you can focus on high-quality products and exceptional service for your customers.

Are you ready to push automation forward?