Customer Testimonial

Cardinal Fasteners Ups Its Productivity with a Third Bar Feeder

Compay Name: Cardinal Fasteners

Website: https://cardinalfastener.com/

Cardinal Fasteners is a subsidiary of Fastenal, and specializes in custom made-to-order nuts, bolts and fasteners of all types.

When it’s critical, it’s Cardinal.

That’s the slogan of Cardinal Fasteners, a subsidiary of Fastenal, which specializes in custom made-to-order nuts, bolts and fasteners of all types. Scott Bertram heads the CNC department at Cardinal Fasteners in Indianapolis, so many of his applications are on Swiss-type machines, which are high-volume with less changeover.

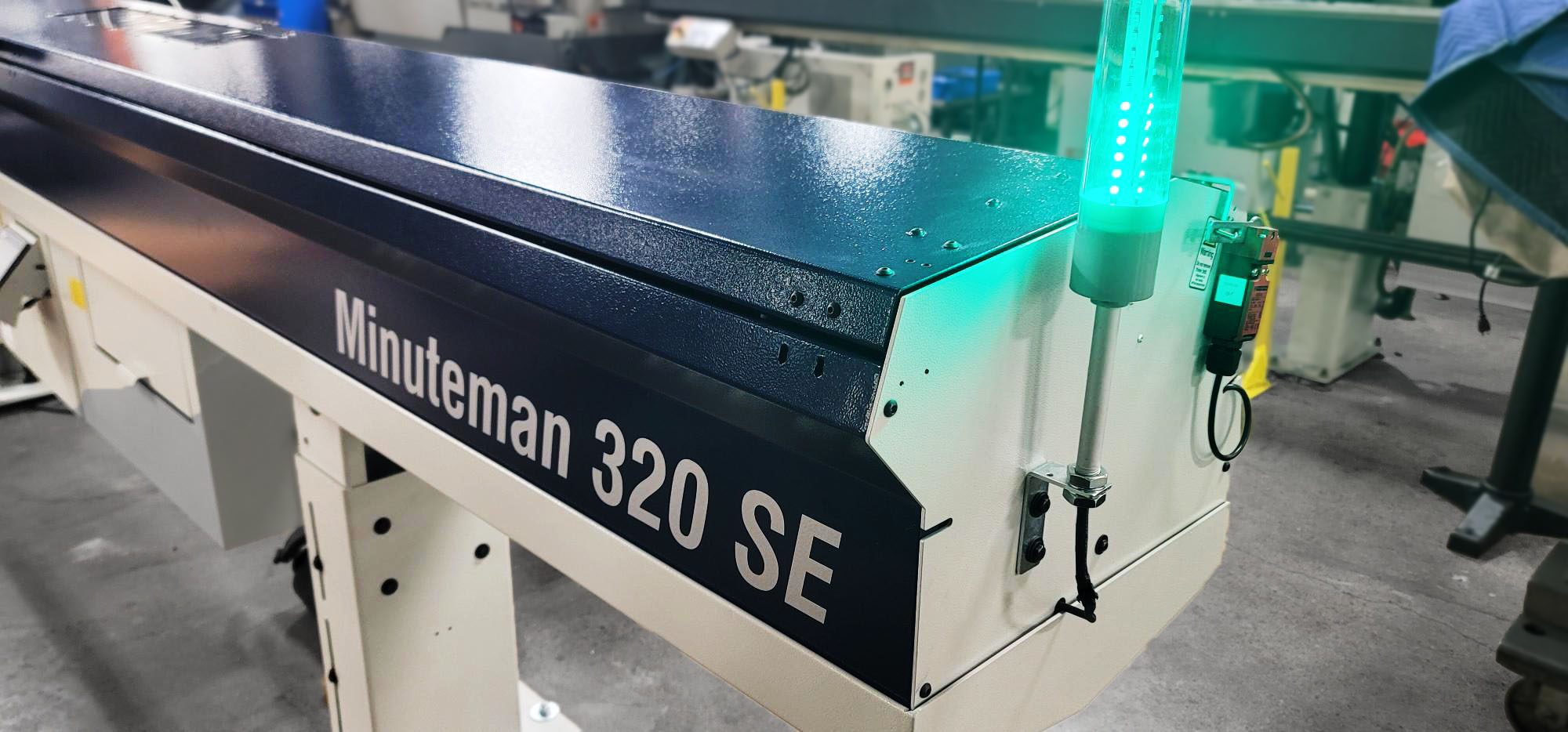

Cardinal has three bar feeders from Edge Technologies. To handle the 12’ bars, Cardinal runs a Patriot 338 on a Hanwha XDI26/32 and an FMB Turbo 2-20 on a Hanwha XD20/26III. Recently, they invested in a Minuteman 320 for another Hanwha XD20/26III.

“We stuck with Edge, because that’s what the home office (in Winona, Minn.) was using, and I’ve used them in the past, and I like them,” Scott said.

Intuitive and User-Friendly HMI

Cardinal prides itself on having the shortest lead times (as fast as same-day) of any manufacturer in the world, so constant run is important to them. Because many of the parts they produce are 4-5” long, the bar feeder can run for hours before they need to add more bars, gaining them an edge in productivity, Scott said.

Scott likes the bar feeders for their intuitive HMI, especially on the Minuteman 320 where changeover time is as simple as changing the part length on the controller.

“It’s a lot more user friendly for the operator,” he said.

“I like the bar feeders for their intuitive HMI, especially on the Minuteman 320 where changeover time is as simple as changing the part length on the controller. It’s a lot more user friendly for the operator.”

Openness and Willingness to Impart Knowledge

Scott also appreciates the customer support. The day of installation, field service technicians explained all the setup, and had the installation complete in less than a day. Later, Scott reached out with a question, and within a couple of hours had an answer and was up and running.

But what really impressed him was the openness and willingness of the field service technicians to impart knowledge. One of the field service technicians was newer, so the more experienced of the two took time to explain important details, rather than just doing it himself. When one of Scott’s machinists brought up minor issues they’d experienced with the older Patriot 338, the technicians even took time to troubleshoot.

“The knowledge was there,” Scott said. “And I’m a team leader, so I recognize when a more experienced technician shows how something is done and explains why. I was very impressed.”