Customer Testimonial

Edge Technologies Helps Geospace Technologies Save Money, Advance Lights-Out Production and Build New Machine Capabilities

Compay Name: Geospace Technologies

Website: https://www.geospace.com/

Geospace is a Houston-based oil and gas seismic surveying company that is vertically integrated, meaning its in-house machine shop produces support items for things like molding, machining, connectors and circuit boards.

Since becoming a machine shop manager at Geospace Technologies, Justin Henry has focused on cost savings, lights-out production and new machine capabilities.

Geospace is a Houston-based oil and gas seismic surveying company that is vertically integrated, meaning its in-house machine shop produces support items for things like molding, machining, connectors and circuit boards. Recently, the company has moved towards adding external work with contract manufacturing, which has called for greater lights-out production capabilities.

Some of Justin’s job duties include weighing the costs between whether Geospace should make parts internally or request proposals from other shops to produce the same quality for cheaper.

“I’m really big on USA manufacturing and automation,” Justin said, “and the best way to do that on a lathe is with a bar feeder, so it seemed like a no-brainer to invest in one.”

When considering a bar feeder, the name Edge Technologies kept turning up no matter which machine tool dealer Justin visited.

“They kept saying Edge Technologies is highly reputable and produces reliable machines,” Justin recounted.

“I Knew Edge Was the Only Way to Get to Unattended Machining”

So Justin called Edge. He was instantly connected to the right person who explained how the machine worked, and why it was so robust. When the bar feeder performed as robustly as promised, Justin invested in a second one. Then he bought a Swiss-type machine, and called Edge, saying, “I have a totally different application. What do you have?” That’s when he acquired an FMB.

“By the fourth machine, I didn’t even have to think about it,” Justin said. “I knew Edge was the only way to get to unattended machining.”

“By our fourth bar feeder investment, I didn’t even have to think about who I would go through. I knew Edge Technologies was the only way to get to unattended machining.”

Product Specifications as Easy as Changing a Couple of Parameters

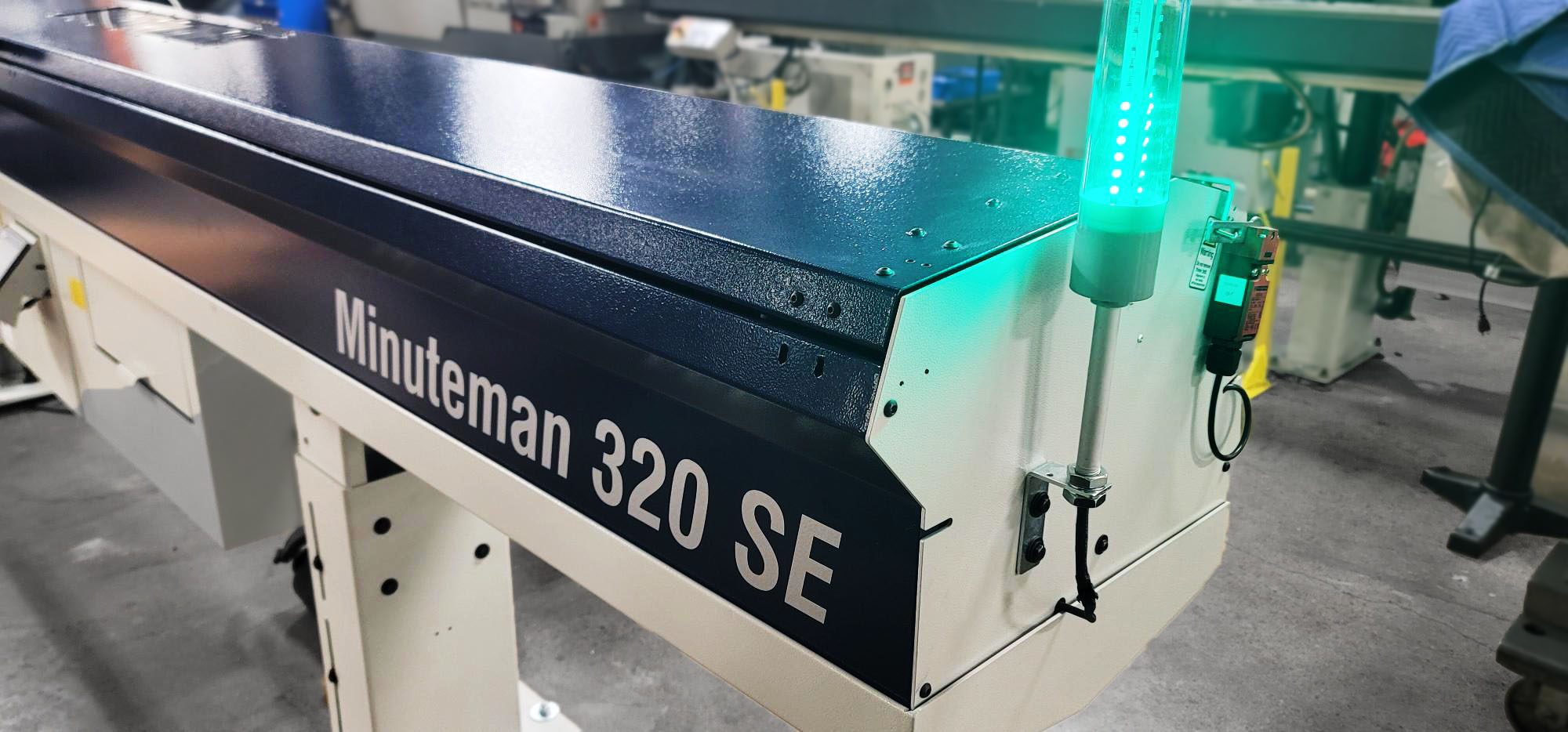

Today, Geospace Technologies runs two Patriot 551s on Samsung SL-15M live tool lathes, one Patriot 551 on a DN Solutions Lynx 2100, and an FMB Turbo 3-38 on a Tsugami 327-5AX Swiss lathe.

One thing Justin appreciates is the ease-of-use. Handling product specifications is as simple as changing a couple of parameters on the controller.

“Edge Technologies’ bar feeders require less guesswork, and they work,” Justin said. “Whatever I give the machine, I know it can handle it.”

This is quite different compared to a few competitor bar feeders Geospace had acquired, which have had ongoing issues of not changing bar diameters appropriately. Those bar feeders always seem to be off-center, Justin said, and no matter how many times his team has tried to recalibrate them, it seems like some misalignment occurs, requiring one of his machinists to be involved, and thus defeating the purpose of a bar feeder.

Not only are Edge Technologies’ bar feeders reliable and robust, the customer service is unmatched.

“For every department of Edge Technologies I’ve had to talk to, everybody has been knowledgeable in their area, and if they weren’t able to answer my question, they’ve referred me to the right person,” Justin said.

It appears Edge Technologies as a company is a well-oiled machine. Pun intended?