Customer Testimonial

Edge Technologies Comes Through in a Crunch to Help Elite Manufacturing LLC Fulfill 20,000-Part Lights-Out Production Order

Compay Name: Elite Manufacturing LLC

Website: https://elite-mfg.business.site

Elite Manufacturing LLC specializes in CNC Swiss machining with the most recent advancements in the machining industry. Equipped with a high-pressure, 12′ magazine bar feeder, chip conveyor, workpiece conveyor and rotary table, Elite Manufacturing LLC runs up to 24 hours a day.

The challenge of machining a perfect part is what made Matt Pokornowski fall in love with the manufacturing industry. Opening his own shop was his dream and goal, and this became a reality in 2021 when he opened Elite Manufacturing LLC. Elite Manufacturing LLC specializes in Swiss machining production work.

Inside the shop, Matt has an FMB Turbo 3-38 attached to a Tsugami B0325V-III. Originally, he went with a competitor’s bar feeder as part of a package deal through an OEM. But then the bar feeder got stuck in port, and, no matter how many phone calls, Matt couldn’t get a clear timeline of when the bar feeder would arrive. This was 2021, when the world was reeling from major supply chain issues.

Matt had production orders of 20,000 parts, and he did not want a bad name for himself.

Smooth and Professional Installation Empowers 24/7 Lights Out Production

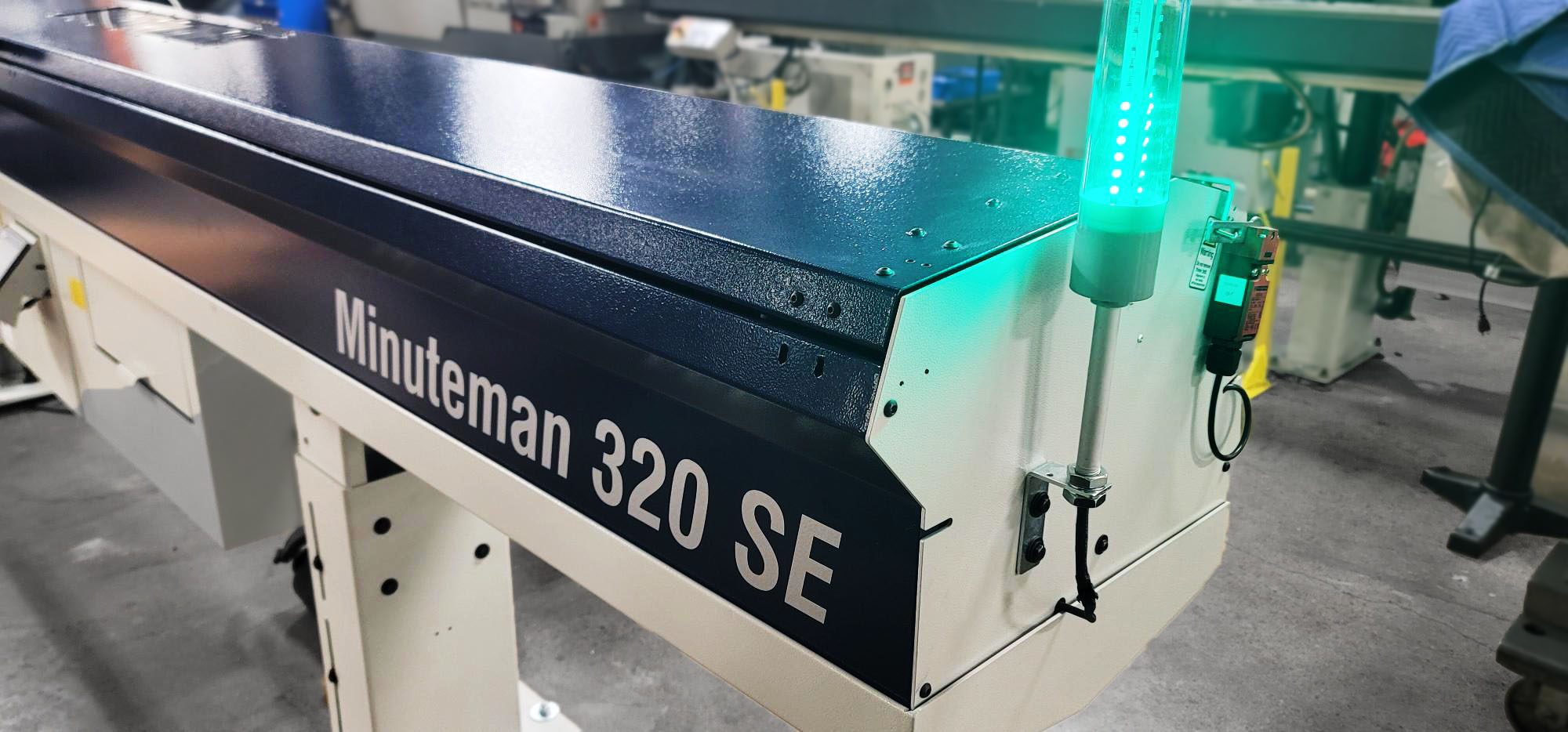

That’s where Edge Technologies was able to help. In less than a month, we installed an FMB Turbo 3-38.

Both the installation and training were smooth and professional, Matt said. The technician scouted the shop the day before, then had the machine bolted down and adjusted, the shrouds cut and placed, and the training complete by the end of the next day.

This was November 2021. Matt ran parts the entire following month, December 2021 – 24/7, lights out production, and was able to catch up on orders with no hiccups.

“Edge Technologies has been great,” Matt said. “Everybody has been easy to work with, and they’ve resolved any issues seamlessly.”

“Edge Technologies has been great. Everybody has been easy to work with, and they’ve resolved any issues seamlessly. I was able to run parts in my shop for an entire month straight, 24/7, lights out production, with no hiccups.”

Lots of Thoughtful Details, Like Isolated Electrical Cabinet and Oil Tank

The FMB Turbo 3-38 is a beefy bar feeder, able to withstand the 12’ bars. Matt also appreciates the thoughtful details that have gone into the machine. Because Edge Technologies’ focus is almost exclusively bar feeding, we spend more time thinking through the details, like isolating the electrical cabinet and oil tank from the machine so that they don’t vibrate.

“That’s something that’s stuck with me,” Matt said. “It just makes sense.”

Elite Manufacturing LLC has been around for 2 ½ years, but Matt has been machining for nearly 14, so this wasn’t his first experience with an Edge Technologies bar feeder. Throughout his career, he can’t really name any major issues he’s experienced with an Edge Technologies bar feeder, other than regular wear and tear.

“Every time I’ve had to call about an issue, I’ve always left the conversation feeling like things were resolved,” Matt said. “Based on my experience, I don’t see why Edge Technologies won’t be a front runner for future purchases.”