Customer Testimonial

Edge Technologies Enables Kager Industries to Switch to a Four-Day Work Week and Still Get More Work Done with Over 50 Bar Feeders

Compay Name: Kager Industries

Website: www.kagerind.com

Kager Industries is a Swiss–type screw machine shop that specializes in electrical connectors, sockets, contacts, small shafts, bushings and screws for fishing reels, archery, the medical industry, government projects, the automotive industry, and even just hobbies and toys.

In 2018, Fred and Robert Kager, owners of Kager Industries, retired a variety of bar feeders that the company had purchased in the late 1970s to run on their Tornos Screw Machines (later adapted to run on Citizen B12E/16E and Citizen A20 lathes). Fred realized that he and his son had been spending more time fixing the old loaders and training their people across all the different types. It was time for a new bar loader, a single type that worked across all lathes.

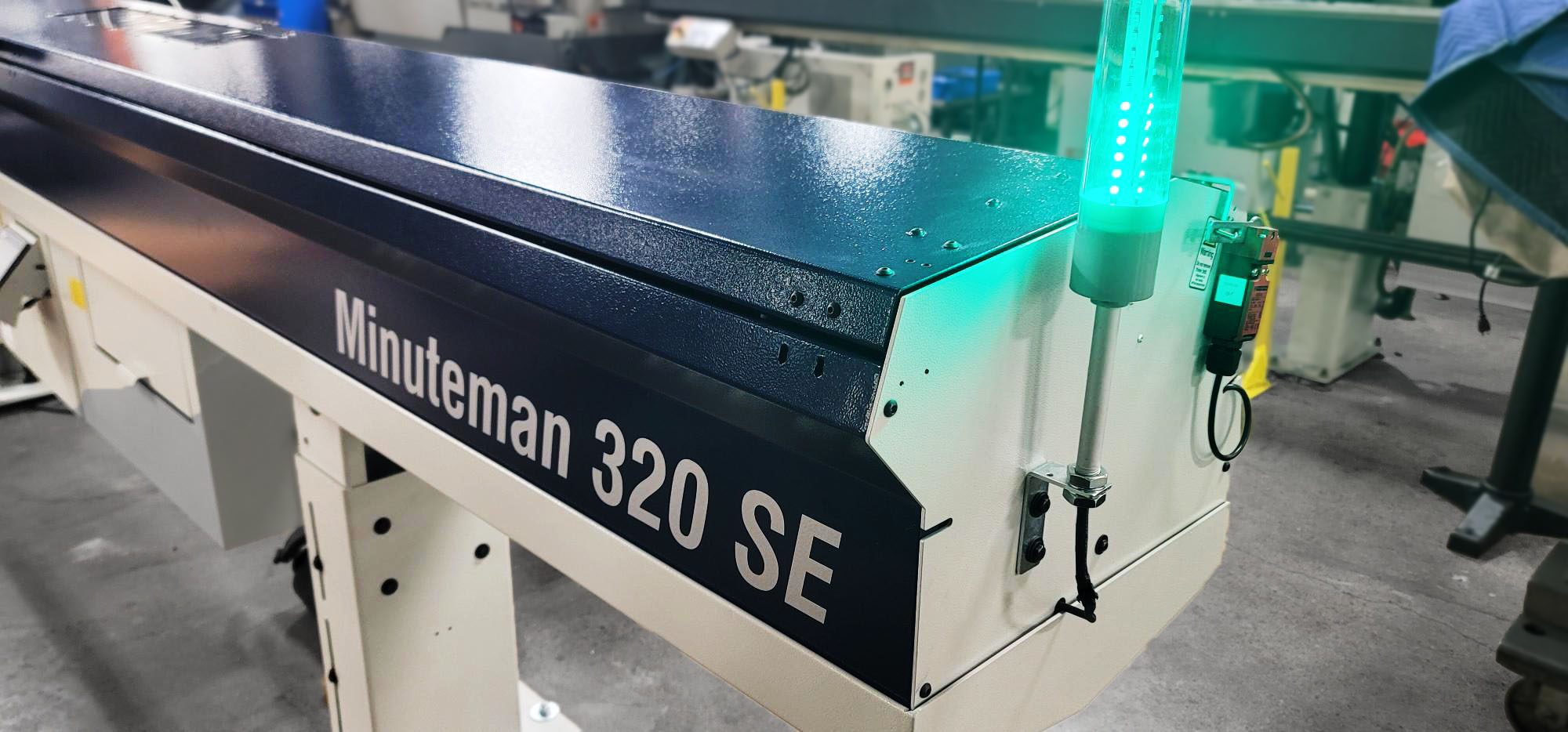

At first, they considered some competitor bar feeders, but, after not enjoying a quality experience, they settled on a Scout 320 from Edge Technologies.

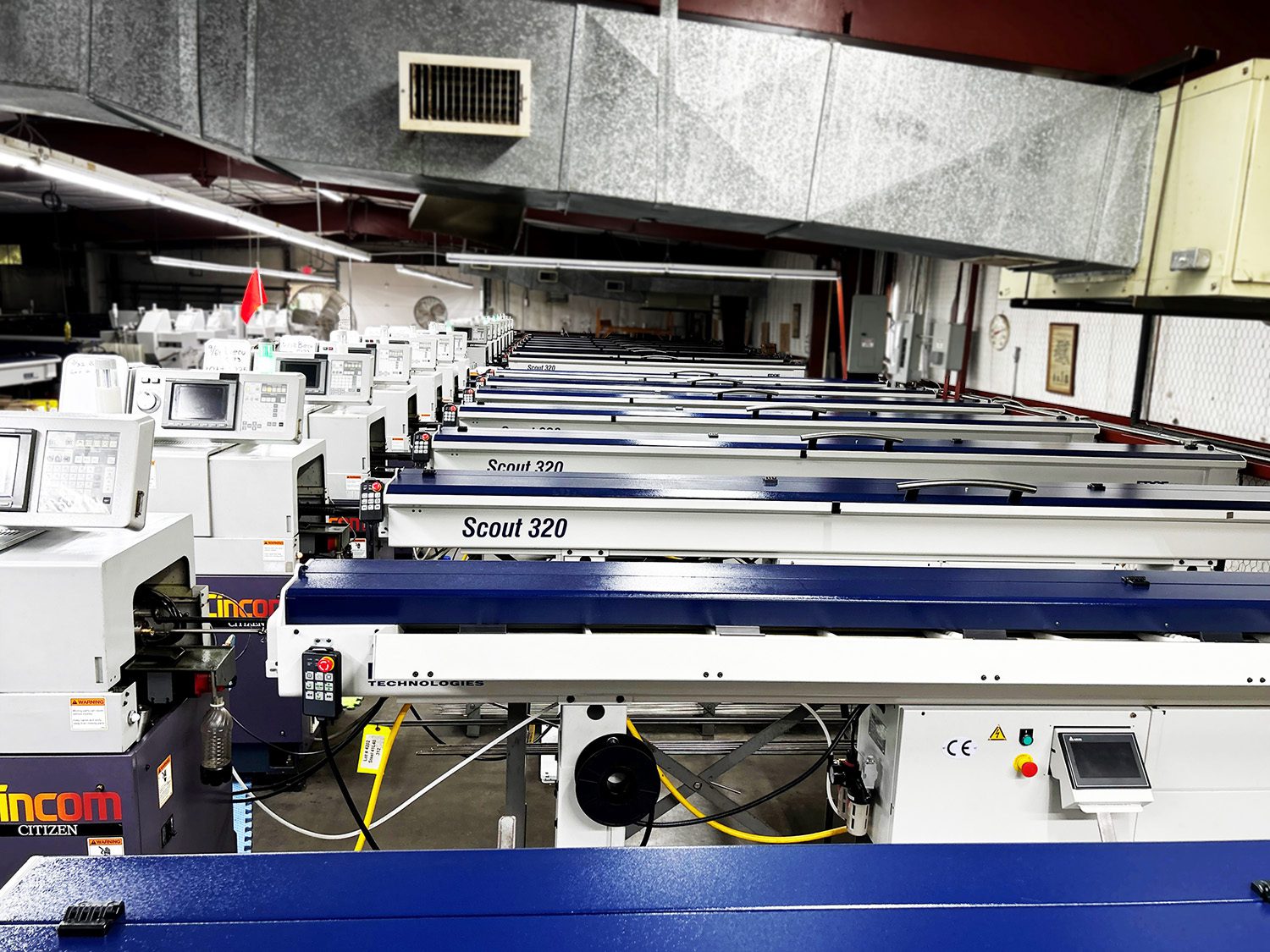

Today, they have over 50 Scout 320s on their shop floor.

A Customized Solution for Over 50 Bar Feeders

One thing that differentiated Edge Technologies was that Edge met all of Kager’s specific requirements, to the point of making customizations on over 50 bar feeders.

“Edge met every one of our requirements and then some,” Fred said. “I can’t say enough positive things. Everything went the way I wanted it to go.”

Since then, Kager Industries has experienced very few issues, and most of those have involved things like operators incorrectly setting a parameter. For the others, Edge responded quickly, troubleshooting and getting it solved, Fred said.

“Edge doesn’t just want to solve the problem for us,” Fred said, “they want to improve the product for everyone else. When you have a supplier that doesn’t just drop you and say, ‘Ok, we’ve got as much money as we can out of this guy,’ but instead says, ‘How can we improve our product?’, you don’t trade them for anything.”

“Edge Technologies set us up for lights out operation, and we were able to switch to a four-day work week. You ask our people — working a four-day week is like heaven. The machines still run 100 hours a week. Now we get more done with fewer days working.”

Lights Out Operation through Scout 320s Has Led to a Four-Day Work Week

The Scout 320s have enabled Kager Industries to switch to lights out operation, with about 40 percent of their bar loaders running through the night.

“It’s been great for my son and me,” Fred said. “It’s freed up our time tremendously.”

Now, the Kagers can concentrate on other aspects of the business, like quality standards and efficiency processes that directly affect their ISO 9001:2015 certification. Thanks to the Scout 320s, they can concentrate on other equipment updates and research new processes.

It’s also freed up their personal time.

Because of the gains from lights out production, Kager Industries switched to a four-day work week. The machines still run 100 hours a week, but all employees work four 10-hour days, and Fridays are completely automated with one guy checking on things.

“Everybody likes that,” Fred said. “You ask our people — working a four-day week is like heaven. Now we get more done with fewer days working.”

Quick-Change Guide Channels and Gripper Features on an Overall Easy-to-Use Machine

Other features that have really helped Kager Industries include quick-change guide channels. Because most of their orders are short run (1,000 pieces or less) with 24-hour turnarounds, fast setups are extremely important.

Fred also loves how the bar feeder gripper inserts the bar into the bar collet without missing a beat, and “self centers,” requiring no additional adjustment.

In all, Fred appreciates that the Scout 320s are easy to learn, maintain and troubleshoot.

“Some of these bar loaders are so complicated that you lose focus on what you’re trying to do,” Fred said. “But the Edge bar feeders have worked flawlessly. They’re just fantastic pieces of equipment, and it’s been great for us.”