Customer Testimonial

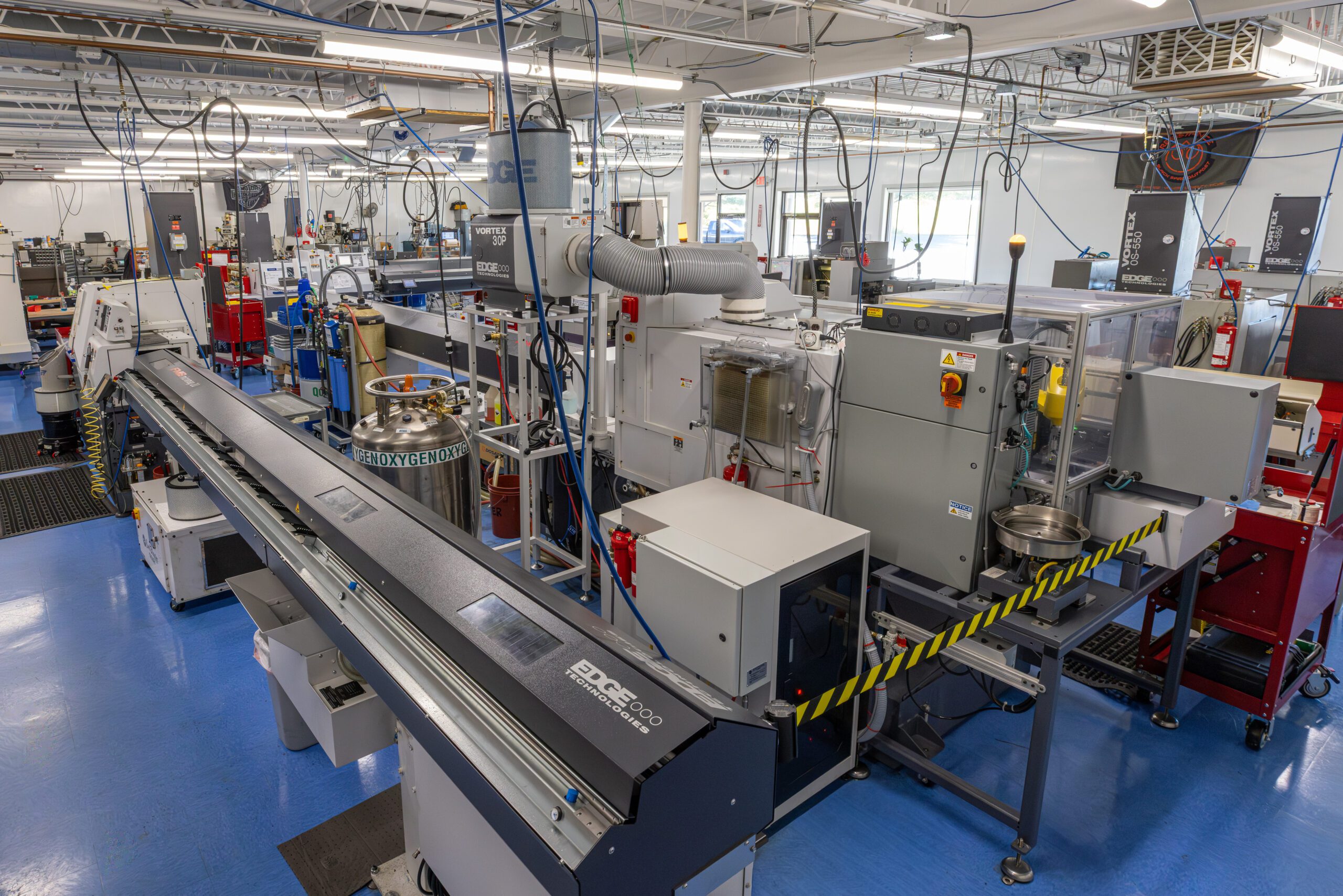

Edge Technologies Helps Transform New England Small Tube Corporation CNC Department with FMB Micromag Bar Feeders and Vortex Mist Collectors

Compay Name: New England Small Tube Corporation

Website: https://nesmalltube.com/

New England Small Tube Corporation specializes in micro stainless-steel tubing, from precision burr-free cutting of stainless steel to the forming and fabrication of complex finished parts and assemblies for industries as varied as biosciences, medical diagnostics, and veterinary services, all the way to fishing lures for deep sea fishing.

To New England Small Tube Corporation, running quarter-inch tubing is considered large stock.

“You have to understand,” said Tom Ceccherini, head of the Swiss CNC Department. “A lot of people say they can go down to 0.8mm, but they’re running solid spring stock. We’re running a literal tube at 1mm O.D. 0.5mm I.D. Very flimsy material.”

Today the company runs:

- 4 Marubeni Citizen-Cincom L12

- 3 Marubeni Citizen-Cincom A20 VII

- 1 Marubeni Citizen-Cincom B12EVI

- 1 Marubeni Citizen-Cincom L20E W/ L2000 laser

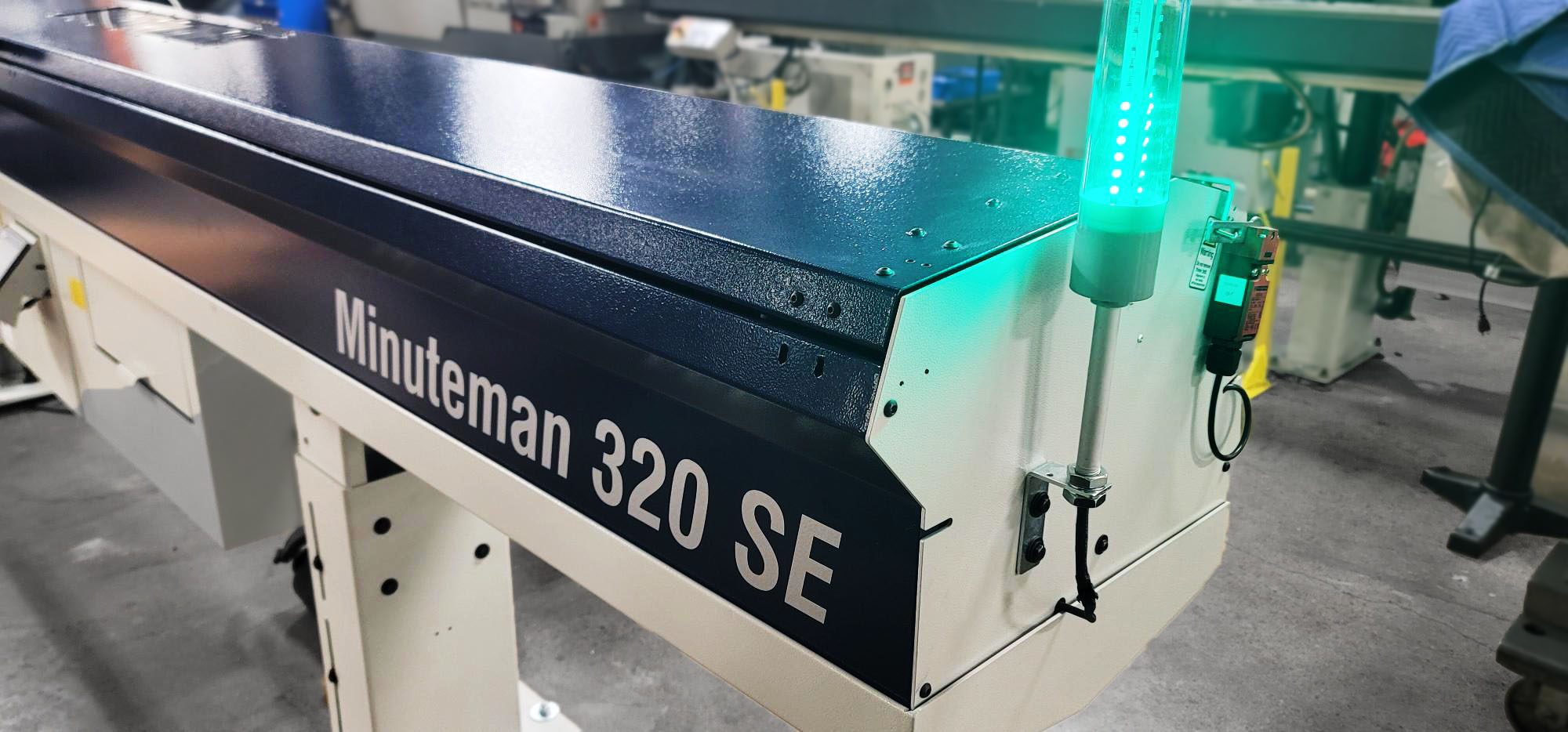

They run five FMB Micromag 20 bar feeders, said Michael Menard, Swiss CNC Supervisor.

Walking Beam Separation, a Single Pusher, and Soft Load Clutch: Why the Micromag 20 Is the Best Fit for Micro Stainless-Steel Tubing

The New England Small Tube Corporation Swiss CNC Machining department launched in 1998. They started with a different bar feeder, one that could handle down to 3mm.

“We got close,” Tom said. “Then we tried the Micromag, and the Micromag really took us to the next level.”

The FMB Micromag 20 is the best fit because it has walking beam separation, a single pusher, and a soft load clutch:

Walking beam separation. A sawtooth walking beam moves bars forward in a stepping motion, keeping them spaced apart, to prevent clumping or jamming.

A single pusher. A single pusher prevents misloads.

Soft load clutch. The soft load grips small stock. With the twist of a knob, the gripper goes soft to protect delicate surfaces from getting damaged.

Thanks to the FMB Micromag 20, New England Small Tube Corporation can run “angel hair spaghetti” inside a Swiss lathe, Tom said. The oil suspends the tubing enough that they don’t get burnouts or bind-ups, and the telescopic nose keeps the integrity of the tube, without birds’ nests behind the guide bushing.

“Unless we subsidize the industry and become New England Big Tube Corporation, I don’t see us going any different at this point,” Tom said. “The Micromag seems to be the best option for us.”

An Automation Solution that Led to 300% Increase in Production

Since adopting the FMB Micromag 20, New England Small Tube Corporation has seen a 300% increase in Micro machining Swiss CNC machining production, Tom said. The machines run at maximum capacity 12 hours a day. Downtime for machines has decreased.

Michael used to take tubes, put them in a fixture, and hand-drill them. Now, where it used to take a minute to do a part manually, the CNC lathe can pump out two to three parts. The Micromags even keep up with all the very small, quick movements.

And the support from Edge Technologies has been exceptional, Tom said. When the Micromags were installed, two field service technicians explained the process quickly and clearly. When New England Small Tube Corporation ran into issues, the technicians worked with Tom and Michael to come up with a solution that best fit their needs.

And since then, any calls Tom has had to make for support have been returned quickly.

“You have to understand. A lot of people say they can go down to 0.8mm, but they’re running solid spring stock. We’re running a literal tube at 1mm O.D. 0.5mm I.D. Very flimsy material. The FMB Micromag 20 really took us to the next level.”

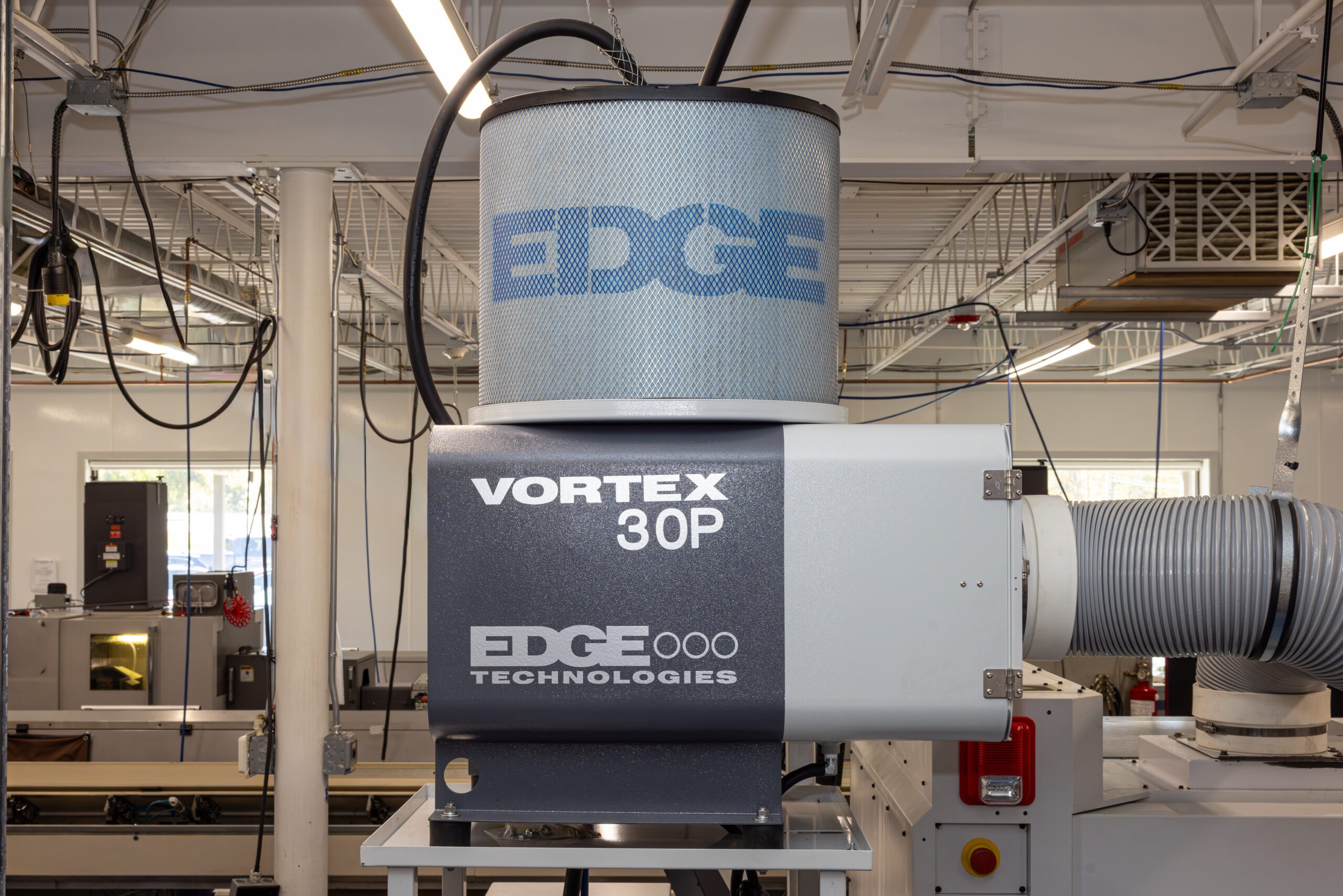

Vortex Mist Collectors: The Best Mist Collector Out There

For New England Small Tube Corporation, “shipping shiny” is part of what makes Small Tube Small Tube, Tom said. So they use a lot of high-pressure coolant to push chips off.

Problem is, that coolant must go somewhere.

Originally, New England Small Tube Corporation went with a competitor’s mist collection device, Tom said, but they constantly ran into issues, like having to replace cells.

“Next thing you know, we have so much mist in our CNC shop that it looks like a Dave Matthews Band concert,” Tom said.

New England Small Tube Corporation shopped around for a few options when Edge Technologies allowed them a trial run on Vortex mist collectors. The Vortex mist collectors use 3-stage replaceable HEPA filters and are not electrostatic, which appealed to Tom, since the original electrostatic mist collectors caused a lot of issues.

Two years after investing in Vortex mist collectors, the units still had a good amount of pull, and New England Small Tube Corporation hadn’t even had to change a single HEPA filter.

“After we saw that result, we thought this is a no brainer,” Tom said. “We replaced every one of our mist collectors with Vortexes.”

Vortex Mist Collectors Save Money, Improve Safety and Morale

Because New England Small Tube Corporation no longer pays a fee to have someone change out cells — all they have to do is swap out a HEPA filter — the company has reduced maintenance by thousands of dollars, Tom said.

But it’s more than just saving a few bucks. It’s also improved employee morale.

“Some of our employees were concerned with the overall air quality,” Tom said. “But we made the switch and things have really improved. It’s no longer something you immediately notice or feel. The entire space is much more comfortable to work in now.”

Now, employees can see the other side of the room. The tops of the machines aren’t coated in oil. Open laptops don’t have a film over them. The area looks more like a showroom than a shop floor, Michael said.

“It’s a lot easier to breathe in here,” Michael said. “Plus, my wife hasn’t complained about me smelling like oil for a while.”