Customer Testimonial

Mid America Screw Products Sees 20% Increase in Spindle Utilization with Edge Technologies Bar Feeders

Compay Name: Mid America Screw Products

Website: https://masinserts.com/

Mid America Screw Products specializes in machine inserts for rotational molding companies (on products ranging from kayaks to coolers to dog kennels, you name it), reporting sales between 8 million and 12 million inserts a year.

In 2022, Mid America Screw Products’ workload got so heavy, they realized it was time to up the technology. So they introduced Swiss CNC capabilities to the shop floor.

Adam Fugate, General Manager of Mid America Screw Products, selected Edge Technologies for bar feeding automation, because Mid America Screw Products runs a lot of hex material, and they needed a beefier bar feeder. The FMB Turbo 5-65, for example, has a cast iron base that dampens vibrations 10x more effectively than steel.

Today, Mid America Screw Products runs:

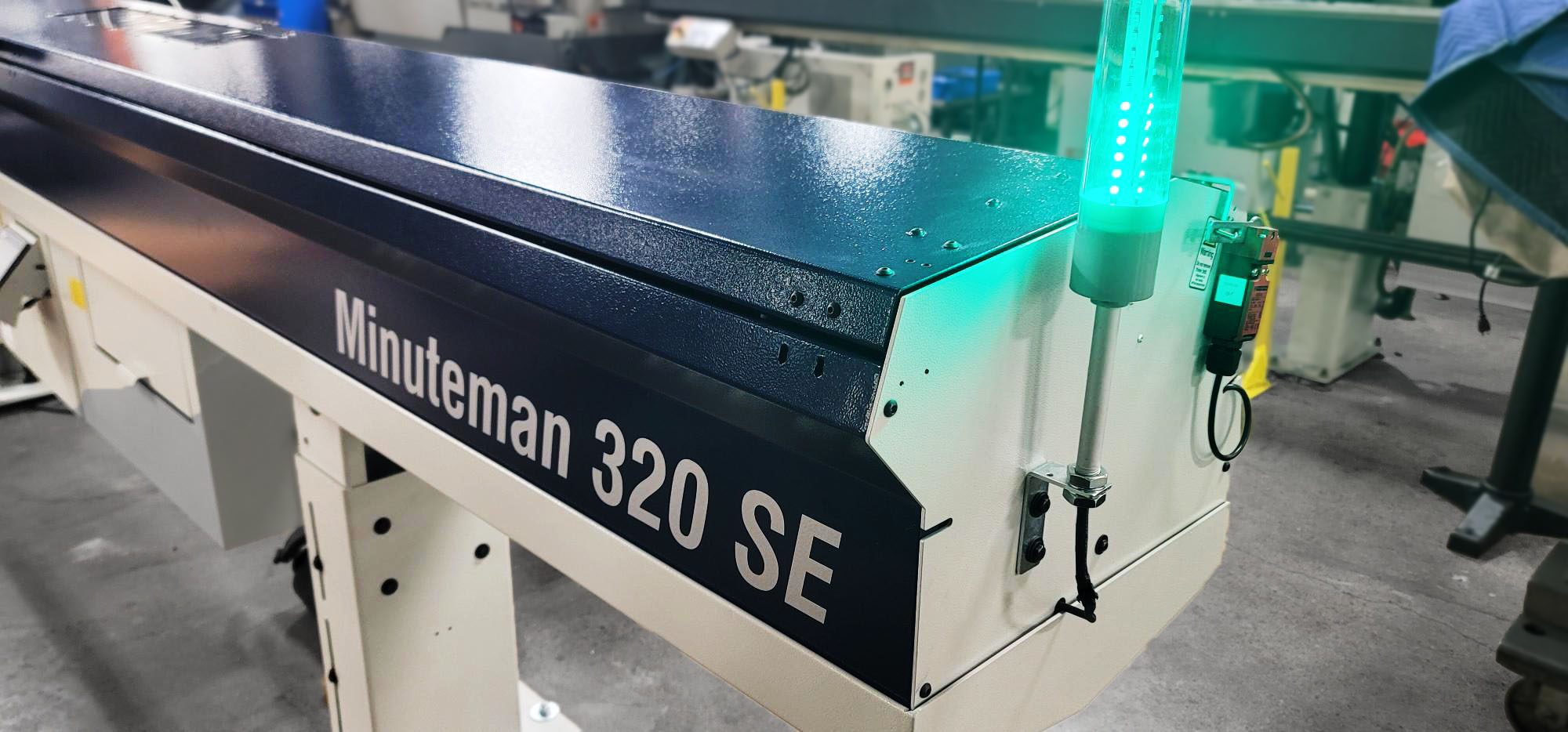

- 1 Scout 320 bar feeder on a Citizen L25 lathe

- 1 FMB Turbo 5-65 on a Miyano BNE-51MSY

- 1 FMB Minimag 20 on a Citizen A20

More Time for Operators to Focus on Daily Maintenance and Shop Organization

The bar feeders have freed operators to run more than one machine at a time.

“Once they get the job set and machines dialed in, they’re checking parts at certain intervals,” Adam said, “but they don’t have to worry about reloading the machine, so our efficiency increases.”

Operators can instead focus on daily maintenance and shop organization.

“It’s great,” Adam said. “The machines run through break. You kind of set them and forget them.”

But it’s not just increased efficiency with operators. The automation of the bar feeders has improved processes as well.

20% Increase in Spindle Utilization

One of Mid America Screw Products’ operations is a bulkhead fitting with a counterbore on the backside. Originally, when they relied on the multi-spindle machines, the application required two secondary operations – “a huge bottleneck,” Adam said.

With the Swiss CNC machines, Mid America Screw Products can run the pieces complete.

Even though the cycle time from beginning to end is a little slower, having no secondary operations has increased Mid America Screw Products’ spindle utilization from 70% to 90%.

But the biggest advantage comes with running lights out.

“If we have a hot job, we pop in around 10 or 11 p.m., check everything, then set the machine to run another eight hours. It’s enabled us to fulfill one repeat customer’s order of 10,000 303 Stainless Steel inserts per week.”

Lights Out Production Adds 14 Hours of Spindle Utilization a Day

For some simpler applications that have tolerances of plus or minus 10, Mid America Screw Products runs lights out production. After running one 10-hour shift, they get an additional 14 hours of spindle utilization a day. That adds up to roughly 160 production hours per month.

“If we have a hot job, we pop in around 10 or 11 p.m., check everything, then set the machine to run another eight hours,” Adam said.

One of Mid America Screw Products’ repeat customers requested 10,000 303 Stainless Steel inserts per week. Adam did the math and determined, if he was to use multiple single-spindle machines, it would take 18 production days to meet the 1-week requirement. But with the Swiss CNC lathes, the team reduced cycle time by 12 seconds (from 45 seconds to 37), increased efficiency by 20%, and ran lights out, enabling them to meet the requirement in just five days.

Plus, they didn’t have to sand 10,000 pieces by hand, which would have required getting fingers close to the grinding wheel.

“We lifted employee morale, and saved money on Band-aids,” Adam said.

Six Months to Recover Upfront Costs on Bar Feeders

Adam estimates, with the increased efficiency, he was able to recover the upfront cost on the bar feeders as soon as six months after purchase.

When Mid America Screw Products first started in 1981, they worked out of a garage. Since then, they’ve grown into a 20,000-square-foot manufacturing space full of single-spindle and multi-spindle machines. The move to Swiss CNC machines has increased their capabilities so much, they are now expanding into another 20,000-square-foot building next door.

“We will continue to use Edge Technologies bar feeders as we grow,” Adam said.